Applications of Valve Interlock Systems in the Pharmaceutical Industry

In the pharmaceutical industry, precision, safety, and regulatory compliance are non-negotiable. Every stage of production—from raw material handling to packaging—requires stringent operational controls to prevent contamination, cross-mixing of chemicals, and accidental release of hazardous substances. One of the critical technologies enabling this control is the valve interlock system. These systems, particularly mechanical-coded designs such as Nudango’s valve interlock systems, play an indispensable role in ensuring both operational safety and process integrity.

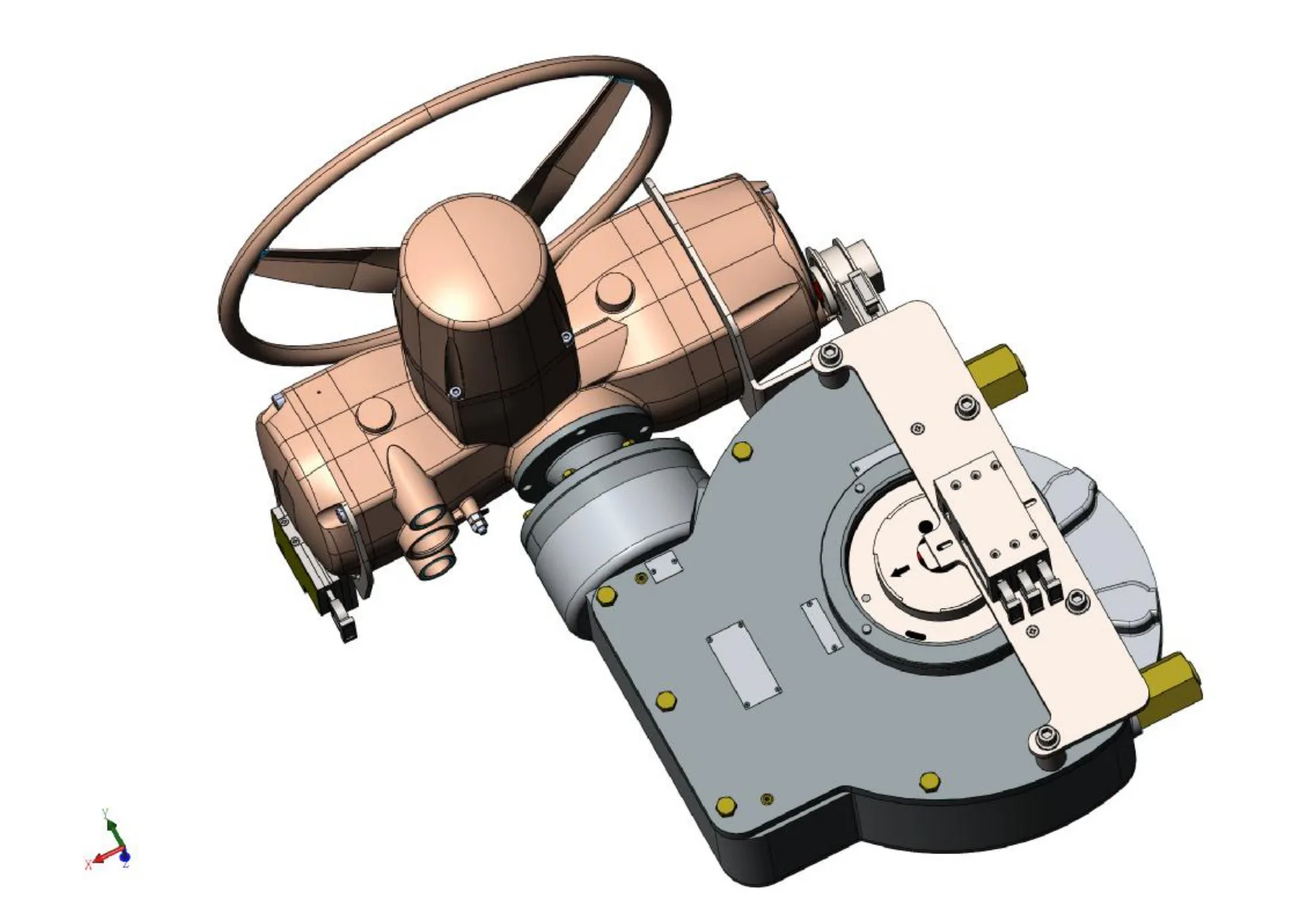

Understanding Valve Interlock Systems

Valve interlock systems are safety devices designed to prevent incorrect operation of valves. In a pharmaceutical plant, the misalignment or incorrect opening of a valve can lead to cross-contamination, chemical hazards, or operational inefficiencies. Mechanical-coded valve interlocks operate on a physical logic: only specific sequences of valve positions allow access to keys or control devices. This logic ensures that valves can only be operated in a predetermined sequence, effectively enforcing operational protocols.

Nudango’s mechanical-coded valve interlock systems are specifically engineered for manual hand valves. Unlike electronic interlocks, which rely on sensors and software, these mechanical systems are highly reliable, require no external power, and are resistant to harsh chemical environments common in pharmaceutical production. The physical key-coding mechanism prevents human error, making them ideal for environments where safety and compliance are paramount.

Key Applications in the Pharmaceutical Industry

1. Preventing Cross-Contamination

One of the most critical concerns in pharmaceutical manufacturing is cross-contamination between different products. Even trace amounts of active pharmaceutical ingredients (APIs) can compromise product purity and patient safety. Mechanical valve interlock systems ensure that valves connecting different production lines, storage tanks, or clean-in-place (CIP) systems cannot be opened simultaneously or in the wrong sequence.

For example, when cleaning a multi-product batch system, the interlock ensures that cleaning solutions flow in a specific order, preventing residual chemicals from contaminating the next product batch. By physically restricting valve operations, Nudango’s interlocks enforce procedural adherence, making accidental cross-contamination virtually impossible.

2. Enhancing Safety in Hazardous Chemical Handling

Pharmaceutical manufacturing often involves handling highly reactive or toxic chemicals. Improper valve operation can result in spills, leaks, or even explosions. Valve interlock systems provide a mechanical safeguard against such incidents.

Consider a process involving multiple chemical reagents stored in separate tanks. A mechanical-coded interlock can be configured so that only one reagent valve is open at a time, and only after certain upstream valves are correctly positioned. This physical sequencing drastically reduces the risk of unintended chemical reactions, protecting both personnel and equipment.

3. Supporting Compliance with Regulatory Standards

Regulatory compliance is a core concern for pharmaceutical companies. Authorities such as the FDA (U.S. Food and Drug Administration) and EMA (European Medicines Agency) mandate strict adherence to operational protocols and documentation standards. Valve interlock systems are often integrated into Good Manufacturing Practice (GMP) workflows because they provide:

Physical assurance of correct operations: Mechanical interlocks prevent human error without relying on operators to remember complex procedures.

Traceability: Keys and coding systems can be documented, showing that valves were operated in the correct sequence.

Audit readiness: Inspectors can verify that interlocks enforce proper process control.

By integrating Nudango’s mechanical-coded valve interlocks, pharmaceutical plants not only enhance safety but also maintain full compliance with regulatory expectations.

4. Streamlining Multi-Stage Production Processes

Pharmaceutical manufacturing typically involves multiple interconnected stages, such as mixing, heating, cooling, filtration, and packaging. Each stage may require precise control over flow paths. Valve interlocks simplify complex workflows by ensuring that valves in one stage cannot be operated until preceding steps are correctly completed.

For instance, in a multi-product production line, a mechanical interlock can prevent the valve for the next production stage from opening until the previous tank is fully drained and cleaned. This sequencing not only prevents contamination but also reduces downtime caused by manual verification and error checking.

5. Integration with Clean-in-Place (CIP) Systems

Clean-in-place systems are critical in pharmaceutical plants to maintain hygiene and reduce manual cleaning efforts. Proper CIP operations require opening and closing valves in a strict sequence to ensure all surfaces are cleaned effectively. Mechanical-coded valve interlocks are ideal in this context, as they enforce the sequence physically rather than relying solely on electronic controls.

Nudango’s interlocks can be tailored to match complex CIP loops, ensuring that cleaning fluids circulate correctly and that manual errors are minimized. This increases cleaning reliability and reduces the risk of residual contamination—a major concern in high-volume pharmaceutical manufacturing.

6. Reducing Human Error in Manual Operations

Despite automation, many pharmaceutical processes still rely on manual valve operations, particularly in batch processing or smaller facilities. Human error, whether due to fatigue, miscommunication, or insufficient training, can have severe consequences. Mechanical-coded valve interlocks reduce this risk by:

Limiting the number of valves that can be operated at a time.

Enforcing correct sequencing through key coding.

Providing a clear physical indication of which valves are accessible.

Because the system relies on physical keys rather than electronic sensors, operators receive immediate, unambiguous guidance, even in environments with low visibility or electrical restrictions.

7. Supporting Multi-Line and Multi-Tank Configurations

Modern pharmaceutical plants often operate multiple product lines or tank farms simultaneously. Mechanical valve interlocks can be customized to manage complex networks of manual valves across several lines. By assigning unique mechanical codes to different lines or tanks, Nudango’s systems prevent operators from accidentally opening valves that connect incompatible lines. This capability is particularly valuable in facilities producing multiple APIs or formulations in parallel, where the consequences of cross-line contamination could be catastrophic.

8. Maintenance and Reliability Benefits

Mechanical-coded interlock systems are robust and require minimal maintenance, a key advantage in pharmaceutical plants where downtime is costly. Unlike electronic systems, they are resistant to:

Power outages

Electrical faults

Harsh chemical environments

Temperature fluctuations

Regular inspections and lubrication are usually sufficient to maintain operational reliability. Furthermore, mechanical systems are easier to troubleshoot, and their failure modes are predictable—an important factor for risk management in critical processes.

Advantages of Mechanical-Coded Systems Over Electronic Interlocks

While electronic interlocks and SCADA integration are becoming more common, mechanical-coded systems offer unique advantages, particularly in pharmaceutical applications:

Simplicity and Reliability: Mechanical interlocks function without power and are immune to software glitches or sensor failures.

Chemical Resistance: They withstand harsh cleaning agents, solvents, and extreme temperatures often used in pharmaceutical processing.

Immediate Physical Feedback: Operators can feel and see whether a valve is locked or accessible, reducing uncertainty.

Cost-Effective Implementation: Mechanical systems require less capital investment and ongoing maintenance compared to complex electronic interlocks.

Compliance Assurance: Mechanical keys can serve as audit evidence of procedural adherence.

These advantages make Nudango’s mechanical-coded valve interlock systems particularly suitable for pharmaceutical plants prioritizing reliability, regulatory compliance, and operator safety.

Conclusion

The pharmaceutical industry demands operational precision, rigorous safety standards, and uncompromising compliance with regulatory guidelines. Mechanical-coded valve interlock systems, such as those provided by Nudango, address these needs by providing a reliable, fail-safe method for controlling manual valves.

From preventing cross-contamination and ensuring safe handling of hazardous chemicals to streamlining multi-stage production processes and supporting clean-in-place operations, the applications of valve interlock systems are extensive. Their mechanical logic ensures that only the correct sequences of operations are possible, dramatically reducing human error and operational risks.

As pharmaceutical manufacturing continues to evolve with increasingly complex production lines and stricter regulatory scrutiny, the role of valve interlock systems—especially robust mechanical-coded designs—will only grow in importance. For facilities seeking to enhance safety, compliance, and efficiency, investing in Nudango’s mechanical-coded valve interlock systems represents a strategic, cost-effective, and highly reliable solution.

www.nudango.com

nudango

Average Rating