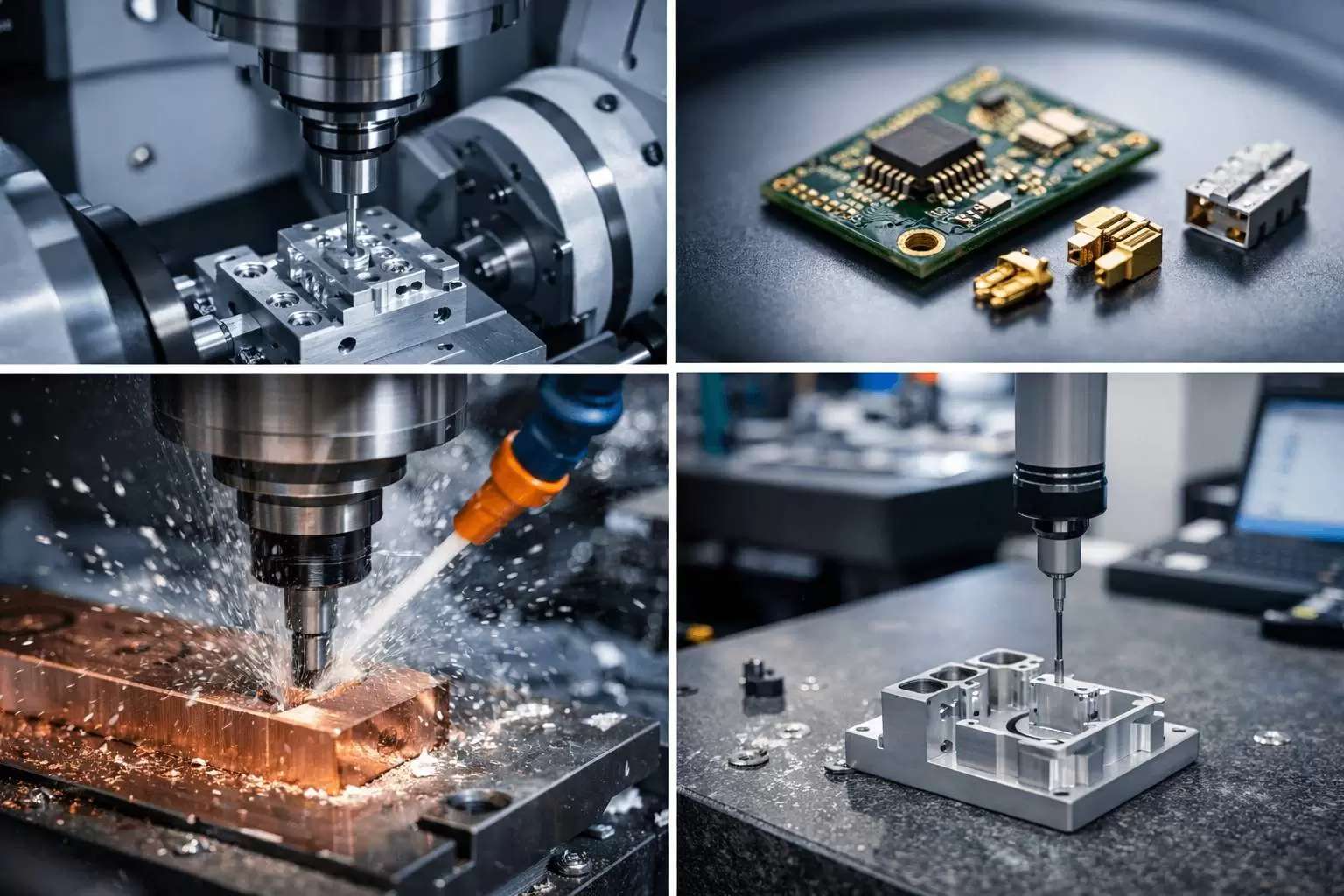

CNC Precision Machining for Electronics: Challenges and Solutions

In today’s fast-paced electronics industry, the demand for highly precise and reliable components has never been higher. CNC precision machining has become a cornerstone technology for manufacturing complex electronic parts, ranging from intricate connectors and housings to heat sinks and sensor components. While CNC machining offers unparalleled accuracy, speed, and repeatability, applying it to electronics manufacturing presents a unique set of challenges. Understanding these challenges and the solutions available is crucial for engineers, manufacturers, and suppliers aiming to deliver high-quality electronic components efficiently.

Understanding CNC Precision Machining in Electronics

CNC (Computer Numerical Control) precision machining is a manufacturing process where pre-programmed computer software controls the movement of machinery and tools to create highly detailed and accurate parts. In electronics, CNC machining is used for:

-

PCB (Printed Circuit Board) substrates

-

Connector housings and pins

-

Heat sinks and thermal management components

-

Sensor housings and micro-mechanical parts

-

Custom electronic enclosures

The process is favored in the electronics industry for its ability to produce components with tight tolerances, often in the range of micrometers, which is critical when assembling devices where even minor deviations can compromise functionality.

Key Challenges in CNC Precision Machining for Electronics

While CNC machining offers exceptional precision, several challenges arise when manufacturing components for electronics:

1. Material Complexity

Electronic components are often made from a wide range of materials, including aluminum, copper, stainless steel, plastics, and specialized composites. Each material has unique machining properties:

-

Aluminum: Easy to machine but prone to burrs and surface scratches.

-

Copper: Highly conductive but soft, leading to tool wear and material deformation.

-

Plastics: Lightweight but can melt or deform under high-speed machining.

-

Composites: Require specialized tooling due to their abrasive nature.

Managing these materials requires careful selection of cutting tools, speeds, and feeds to prevent damage.

2. Miniaturization and Tight Tolerances

Electronics are trending toward smaller and more compact designs, which increases the complexity of machining. Components such as microconnectors or tiny sensor housings often have features measured in fractions of a millimeter. Achieving consistent tolerances in such small geometries is challenging and requires high-precision equipment, stable workholding, and careful calibration.

3. Heat Management

High-speed CNC machining generates heat, which can warp or deform sensitive electronic components. For materials like plastics or composites, excessive heat can cause melting, delamination, or internal stress. Managing heat through optimized cutting parameters, coolant systems, and tool selection is critical.

4. Surface Finish Requirements

Electronic components often require smooth and precise surface finishes to ensure proper assembly, conductivity, or thermal performance. Burrs, rough edges, or surface inconsistencies can compromise electrical connections or hinder assembly, leading to increased rejection rates.

5. Tool Wear and Breakage

Machining hard metals like copper alloys or composite materials accelerates tool wear, which impacts both precision and cost. Frequent tool changes or tool breakage can slow production and reduce overall efficiency.

6. Assembly Compatibility

CNC-machined parts must integrate seamlessly with other electronic components. Slight dimensional errors can cause misalignment, interference, or poor electrical connections. Ensuring assembly compatibility demands rigorous quality control and dimensional verification throughout the production process.

Solutions to Overcome CNC Machining Challenges in Electronics

Despite these challenges, manufacturers can adopt several strategies to achieve high-quality CNC precision machining for electronic components.

1. Material-Specific Tooling and Cutting Parameters

Selecting the right tools and machining parameters is fundamental. For example:

-

Use coated carbide or diamond tools for abrasive materials.

-

Adjust cutting speed, feed rate, and depth of cut according to material hardness and thermal properties.

-

Employ sharp, high-precision micro-tools for miniaturized features.

By tailoring the process to each material, manufacturers can reduce tool wear, prevent deformation, and achieve consistent tolerances.

2. Advanced CNC Equipment

High-precision CNC machines with capabilities such as 5-axis machining, high spindle speeds, and stable thermal compensation are essential for electronics components. Multi-axis machines allow complex geometries to be machined in a single setup, improving accuracy and reducing handling errors.

3. Effective Heat Management

Heat can be managed using:

-

Coolant systems: Flooding or mist cooling to reduce surface temperature.

-

Optimized cutting parameters: Slower speeds or smaller depths of cut for heat-sensitive materials.

-

Intermittent machining: Allowing components to cool between passes.

Proper heat management preserves material integrity and ensures dimensional stability.

4. Precision Fixturing and Workholding

Miniature electronic parts require stable and vibration-free workholding. Customized fixtures, vacuum chucks, and soft jaws prevent movement, minimize deformation, and allow consistent machining across batches.

5. Post-Machining Finishing

Secondary operations such as deburring, polishing, or anodizing help achieve required surface finishes. Automated deburring and inspection systems can ensure high throughput without compromising quality.

6. In-Process Inspection and Quality Control

Average Rating