Enhancing Safety with Distributed Optical Fiber Sensors in Railway Infrastructure

Railway infrastructure is one of the most complex and safety-critical systems in modern society. High-speed rail corridors, urban metros, depots, tunnels, bridges, and power supply networks operate continuously under mechanical stress, environmental changes, and human activity. Any undetected anomaly—track deformation, unauthorized intrusion, cable overheating, or tunnel fire—can escalate into service disruption or safety incidents. This is why the railway industry is increasingly turning to distributed optical fiber sensing as a foundation for next-generation monitoring and early warning systems.

Distributed optical fiber sensors are not a simple upgrade of traditional point sensors. They represent a new sensing paradigm: the optical fiber itself becomes a continuous sensor, capable of detecting temperature, vibration, strain, and acoustic signals along tens or even hundreds of kilometers. For railways that already rely heavily on optical communication networks, this technology offers a practical path toward large-scale, real-time monitoring with controllable cost and deployment effort.

From Communication Fiber to Sensing Infrastructure

Globally, more than four billion kilometers of optical fiber have already been deployed, including over 1.2 million kilometers of submarine cables. Railways alone account for a massive portion of terrestrial fiber, installed along tracks, in tunnels, and inside stations for signaling, communications, and power systems. Traditionally, these fibers have been “silent” in terms of physical perception.

Distributed optical fiber sensor technology changes that. By deeply integrating with existing optical communication cables, it enables “ultra-low-cost” cable upgrades without adding discrete field instruments or dense sensor arrays. In other words, the same fiber used for data transmission can simultaneously sense the physical world.

This capability is particularly valuable for large, linear assets such as railways, where the cost and manpower required to install and maintain traditional sensors scale poorly with distance. Instead of deploying thousands of discrete vibration or temperature sensors, operators can rely on continuous fiber coverage to detect events anywhere along the line.

Why Railways Need Distributed Sensing

Railway systems face a combination of operational, environmental, and security challenges:

-

Track and subgrade monitoring: Ground settlement, landslides, or ballast degradation often generate subtle vibrations or strain patterns before visible damage occurs.

-

Tunnel and bridge safety: Temperature rise, structural stress, and abnormal vibration can indicate fire risks or structural fatigue.

-

Power and signaling cables: Overheating, insulation aging, or external damage to high-voltage or signaling cables can lead to failures.

-

Perimeter and intrusion detection: Unauthorized access, cable theft, or construction activities near the track generate distinct vibration signatures.

-

Extreme events: Earthquakes, heavy rainfall, or secondary disasters require fast situational awareness over long distances.

A wide-area, real-time vibration and temperature monitoring network provides better early warning and decision support. The challenge has always been how to build such a network without prohibitive cost.

Key Technologies: DTS, DAS, DVS, and Beyond

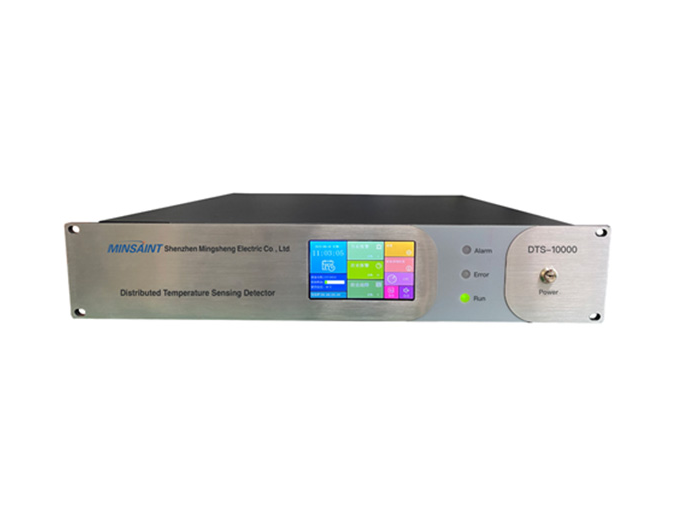

Shenzhen Mingsheng Electrical Co ., Ltd. has developed a comprehensive portfolio of distributed optical fiber sensing equipment designed for infrastructure-scale applications:

-

DTS (Distributed Temperature Sensing) for continuous temperature profiling of cables, tunnels, and equipment rooms.

-

DAS (Distributed Acoustic Sensing) and DVS (Distributed Vibration Sensing) for detecting vibration and acoustic events along rail lines.

-

BOTDA and BOTDR for distributed strain and temperature measurement over long distances.

-

Optical fiber current transformer equipment for power system monitoring.

-

Fiber Bragg Grating equipment for high-precision, localized measurements.

-

Fluorescent optical fiber equipment and various temperature-sensing optical cables tailored to harsh railway environments.

In railway applications, these technologies are not used in isolation. They are combined to form integrated monitoring systems that correlate temperature, vibration, and strain data, providing operators with actionable insights rather than raw signals.

Forward-Transmission Distributed Sensing: A Practical Breakthrough

One of the critical bottlenecks in distributed optical fiber sensing has always been the balance between sensing distance, detection limits, positioning accuracy, and overall system cost. Traditional approaches often require dedicated sensing fibers, specialized light sources, or complex demodulation hardware.

To address these constraints, a new series of distributed optical fiber sensing technologies based on forward-transmitted light has been proposed and engineered. The core idea is to fully reuse existing optical fiber communication systems through shared media, shared channels, and shared signals.

This approach introduces two important innovations:

-

Forward-transmission polarization demodulation: For the first time, polarization changes induced by external physical events are demodulated in the forward transmission direction, enabling sensing without disrupting normal communication.

-

Multi-point vibration separation algorithms: Advanced algorithms make it possible to distinguish and locate multiple simultaneous vibration events along the same fiber, which is essential in busy railway corridors.

By leveraging fibers already installed for communication, railway operators can extend sensing coverage over long distances with minimal additional infrastructure. This significantly reduces deployment complexity and lifecycle cost, while maintaining high positioning accuracy and detection sensitivity.

Integrated Solutions for Railway Scenarios

Beyond sensing equipment, Shenzhen Mingsheng Electrical Co ., Ltd. provides application-oriented solutions that align closely with railway safety requirements:

-

Power online monitoring systems to track temperature and operating conditions of traction power cables and substations.

-

Comprehensive station security systems that integrate vibration sensing with video and access control for early intrusion detection.

-

Highway and submarine tunnel online monitoring systems, directly applicable to railway tunnels, for fire detection, deformation monitoring, and emergency response.

-

Building fire online monitoring systems and ultra-early electrical fire detection systems for stations, depots, and control centers.

-

Pipeline safety early warning systems that share similar principles with cable protection along railway corridors.

-

Synesthetic technology systems, enabling multi-sensor fusion and unified situational awareness.

For example, in a railway tunnel, a single optical fiber cable can simultaneously act as a linear heat detector, an acoustic sensor for abnormal sounds, and a vibration sensor for structural changes. When combined with intelligent analysis software, the system can differentiate between routine train operations and abnormal events such as cable overheating or unauthorized entry.

Toward a Global Physical Information Network

The broader significance of distributed optical fiber sensing extends beyond railways. Ocean information networks, natural disaster monitoring (earthquakes, tsunamis, landslides), and national infrastructure such as high-speed railways and high-voltage transmission lines all share the same fundamental requirement: large-scale, reliable, real-time perception of physical events.

If communication fibers can be efficiently and intelligently upgraded to sense the physical world, a global information acquisition network becomes feasible at a fraction of the traditional cost. Through multi-sensor fusion, this network can support the evolution of next-generation Internet of Things systems that are not limited by dense sensor deployment.

For railway operators, this vision translates into practical benefits today: earlier warnings, fewer blind spots, reduced maintenance workload, and improved operational safety.

Learn More About Integrated Distributed Sensing

The integration of sensing and communication is a key direction for future infrastructure monitoring. For a detailed overview of distributed sensing and communication-integrated sensor technology, the following reference provides additional technical insights:<a href="https://www.minsaint.com/distributed-sensing---communication-integrated-sensor.html">

Distributed Sensing – Communication Integrated Sensor</a>

Conclusion

Railway safety depends on visibility—knowing what is happening along hundreds of kilometers of assets, in real time, and with sufficient precision to act early. Distributed optical fiber sensors provide a realistic and scalable way to achieve this visibility by transforming existing communication fibers into continuous sensing networks.

By combining advanced distributed sensing technologies, forward-transmission innovations, and application-focused solutions, Shenzhen Mingsheng Electrical Co ., Ltd. supports railway operators in building safer, smarter, and more resilient infrastructure. As rail networks continue to expand and operate under increasing demands, distributed optical fiber sensing is poised to become a foundational technology rather than an optional add-on.

www.minsaint.com

Shenzhen Mingsheng Electrical Co ., Ltd. ( MINSAINT)

Average Rating