How High-Speed Five-Axis Cradle Machining Centers Revolutionize Precision Manufacturing

Precision manufacturing has always been a core driver behind the advancement of industries such as aerospace, automotive, medical devices, and high-end electronics. As product designs become increasingly complex and require higher accuracy with tighter tolerances, the tools and technologies used in the manufacturing process must evolve accordingly. Among these, high-speed five-axis cradle machining centers have emerged as transformative solutions, redefining what is achievable in terms of efficiency, precision, and versatility. This article explores the remarkable impact of these machining centers, with a particular focus on their integration into precision manufacturing environments and the role of companies such as Suzhou Zhiquan Electromechanical Equipment Co., Ltd., which produces and sells CNC machining centers, wire cutting machines, electric discharge machines, milling machines, and other equipment essential to modern manufacturing.

The Concept of Five-Axis Cradle Machining

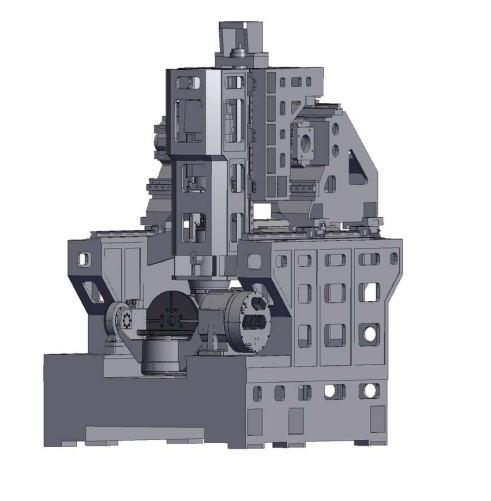

Five-axis machining refers to the ability of a machine to move a tool or workpiece along five different axes simultaneously. Traditional three-axis machines operate on the X, Y, and Z axes, whereas five-axis machines add two rotary axes, typically referred to as A and C or B and C, depending on the configuration. The cradle design specifically allows the workpiece to rotate or tilt, enabling the cutting tool to approach the part from virtually any angle. This capability eliminates the need for multiple setups and reduces repositioning errors.

In high-speed machining, spindle speeds and feed rates are significantly increased compared to standard operations, allowing manufacturers to remove material more quickly while maintaining precision. Combining high-speed performance with a five-axis cradle configuration results in a powerful platform capable of producing complex geometries, intricate contours, and high-quality surface finishes.

Advantages of High-Speed Five-Axis Cradle Machining Centers

The integration of high-speed five-axis cradle machining centers offers a wide range of advantages for precision manufacturing:

Enhanced Accuracy and Precision: By minimizing the number of setups and ensuring optimal tool orientation, these machines reduce cumulative errors and deliver superior dimensional accuracy.

Improved Surface Quality: The ability to maintain consistent cutting angles and avoid abrupt tool changes leads to smoother surface finishes, reducing the need for post-processing.

Greater Flexibility: Five-axis machines handle complex parts that would be impractical or impossible with conventional equipment, supporting a wider variety of projects and industries.

Reduced Production Time: High-speed operations combined with multi-axis movement dramatically shorten production cycles, improving overall efficiency.

Cost Efficiency: Fewer setups, less rework, and higher throughput result in significant cost savings over time.

Applications in Precision Manufacturing

High-speed five-axis cradle machining centers have found their place in numerous industries where precision is paramount. In aerospace, they enable the production of turbine blades, structural components, and engine parts with highly complex geometries. Automotive manufacturers use them for creating molds, precision components, and prototype parts with tight tolerances. In the medical field, the ability to produce custom implants, surgical instruments, and orthopedic devices with exceptional accuracy is a key advantage.

Electronics and semiconductor industries benefit from these machines for producing intricate housings, heat sinks, and precision connectors. Their capacity for high-speed, multi-axis cutting makes them ideal for low-volume, high-value manufacturing as well as high-volume production of complex parts.

Role of Suzhou Zhiquan Electromechanical Equipment Co., Ltd.

Suzhou Zhiquan Electromechanical Equipment Co., Ltd. plays a significant role in advancing precision manufacturing by providing a comprehensive range of machinery, including CNC machining centers, wire cutting machines, electric discharge machines, and milling machines. With a strong focus on research, development, and customer-centric innovation, the company supplies equipment that meets the rigorous demands of modern manufacturing.

Its high-speed CNC machining centers are designed to integrate seamlessly into production lines that require multi-axis machining capabilities. By delivering reliable, high-performance equipment, Suzhou Zhiquan Electromechanical Equipment Co., Ltd. helps manufacturers achieve higher levels of precision, productivity, and competitiveness.

Impact on Manufacturing Workflows

The implementation of high-speed five-axis cradle machining centers transforms traditional manufacturing workflows. Previously, complex parts required multiple setups across different machines, with each transition increasing the risk of errors and extending production timelines. Now, manufacturers can consolidate these processes into a single machining operation, from roughing to finishing.

This consolidation minimizes handling and improves consistency across batches. It also enables just-in-time manufacturing strategies, as production lead times are significantly shortened. Operators benefit from more intuitive machine interfaces, advanced simulation tools, and automatic toolpath optimization, all of which contribute to a smoother production process.

Challenges and Considerations in Implementation

While the benefits of high-speed five-axis cradle machining centers are clear, their adoption requires careful planning and consideration. Factors such as machine cost, operator training, programming complexity, and maintenance must be addressed to ensure a successful integration.

Average Rating