How Sunlike Machinery Helps You Diagnose Pneumatic Flow Control Valve Issues in 2026

Sunlike Machinery leads in finding problems with the pneumatic flow control valve. Their smart tools and expert workers help factories keep systems working well. Sunlike fixes problems quickly and correctly, so machines do not stop for long. This helps production lines stay fast and smooth. The company has important certificates and works with many other businesses. People all over the world trust Sunlike as a top company.

Key Takeaways

-

Sunlike Machinery uses smart sensors to watch pneumatic flow control valves. This helps find problems like leaks and stiction early.

-

Regular maintenance checks are important. Cleaning and looking at seals can stop sudden breakdowns. This keeps production lines working well.

-

Remote troubleshooting support lets experts find problems fast. This saves time and means fewer on-site visits are needed.

-

Predictive maintenance technology warns teams about possible failures before they happen. This helps save money and makes machines last longer.

-

Sunlike gives training and worldwide support services. This helps workers take care of and fix pneumatic systems well.

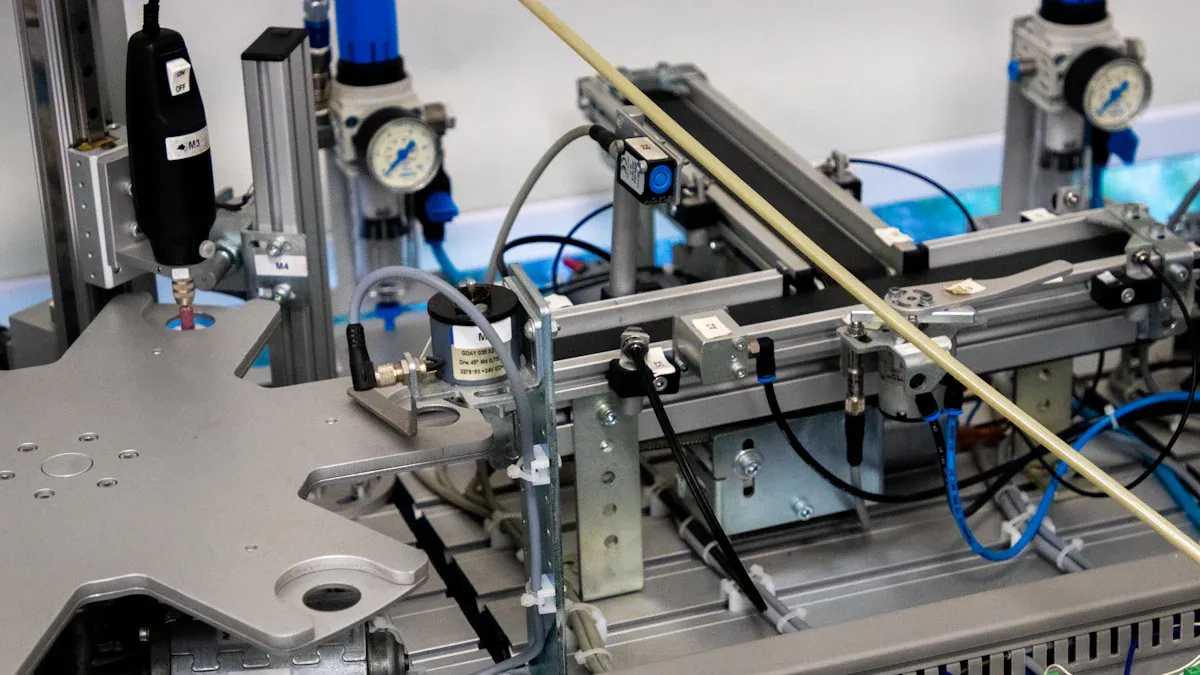

Sunlike’s Diagnostic Solutions for Pneumatic Flow Control Valves

Sunlike Machinery uses new technology and works with other companies. This helps factories keep pneumatic control valves working well. Their certified systems help workers find problems fast and fix them right. This means machines stop less and work better.

Smart Sensors and Real-Time Monitoring

Sunlike puts smart sensors in their pneumatic flow control valve systems. These sensors watch pressure, friction, and air flow. The table below lists the main sensor types and what they do:

|

Sensor Type |

Functionality Description |

|---|---|

|

Built-in Pressure Sensors |

Help check valves better, like valve signature, friction force, and air-circuit watching. |

Real-time monitoring uses IoT to find small leaks and check how fast valves move. The system sends alerts if it finds a problem. Workers can fix things quickly, so valves keep working. Wireless vibration sensors and pressure transmitters help find problems like stiction or slow actuator movement early. This way, factories do not need emergency repairs as often and stay efficient.

Remote Troubleshooting Support

Sunlike gives remote support for pneumatic control valves. Their wireless technology lets experts check valve data from anywhere. This support has many good points:

-

Early fault detection stops sudden failures.

-

Predictive maintenance uses data to plan service before problems get worse.

-

Remote troubleshooting saves time and money by needing fewer visits.

-

Performance optimization helps pneumatic valves work their best.

With these tools, Sunlike helps users fix problems faster and keep systems working well.

Custom Diagnostic Tools

Sunlike makes custom diagnostic tools for pneumatic flow control valve systems. The table below shows some advanced technologies they use:

|

Technology Type |

Description |

|---|---|

|

Wireless Capabilities |

Lets workers use wireless for setup and checking. |

|

Advanced Diagnostics |

Advanced diagnostics with AS-interface (ASi-5), managed with Stonel Wireless Link app. |

|

Bluetooth Wireless Access |

Makes troubleshooting easy, so workers can spot problems early and keep the plant running. |

These tools give workers clear data and easy ways to check valve performance. Sunlike’s certified solutions help users find and fix problems fast, so pneumatic control valves stay in good shape.

Troubleshooting Common Issues with Pneumatic Control Valves

Factories often have problems with pneumatic control valves. These problems can stop machines and slow down work. Sunlike Machinery helps people fix these problems. They give easy steps and special tools for finding issues. The table below shows common problems, why they happen, and how to fix them.

|

Issue |

Causes |

Solutions |

|---|---|---|

|

Valve Stiction |

Dirt, improper lubrication, tight packing |

Clean, lubricate, adjust packing |

|

Air Supply Problems |

Leaks, blockages, faulty regulators |

Inspect, replace tubing, calibrate regulator |

|

Actuator Malfunctions |

Worn parts, seized pistons, wrong sizing |

Replace, inspect, ensure proper sizing |

|

Valve Hysteresis |

Poor calibration, mechanical wear |

Recalibrate, replace worn parts |

|

Seat Leakage |

Damaged seats, misalignment |

Inspect, replace, align seats |

|

Sluggish Response |

Low air pressure, blocked lines |

Ensure airflow, clean, lubricate |

|

Valve not operating |

Internal leakage, actuator failure |

Inspect actuator, check for leaks |

Detecting Leaks and Air Supply Problems

Leaks are a big problem in pneumatic control valves. Air leaks make valves move slowly or not close all the way. Workers should check for leaks in seals and packing. Most failures come from bad seals. Air supply problems cause fewer failures. Signs of trouble are when valves do not work right. To find and fix leaks, workers should:

-

Check all connections for air leaks.

-

Listen for hissing sounds near the valves.

-

Use Sunlike’s smart sensors to find leaks inside.

-

Change broken seals and tubing.

Tip: Checking for air leaks often helps stop breakdowns and saves money.

Addressing Valve Stiction and Hysteresis

Sometimes valves stick or move slowly. They may also move back and forth too much. Stiction happens when seals are old, packing is dirty, parts are not lined up, or there is not enough oil. Hysteresis comes from friction, magnet problems, or loose parts. Bad valves may not close or move right. To fix these problems:

-

Clean and oil valve stems.

-

Make packing tighter.

-

Put in new seals.

-

Recalibrate positioners to fix hysteresis.

Fixing Alignment and Actuator Issues

If parts are not lined up or actuators are broken, valves may not work. Worn parts or wrong sizes can cause problems. Valves may move slowly or not at all. To fix these issues:

-

Check actuators for damage or wear.

-

Make sure all parts are lined up right.

-

Change broken parts.

-

Use Sunlike’s tools to check actuators.

Note: Fixing valve problems fast helps machines work well and stops long delays.

Step-by-Step Troubleshooting Guide

Initial Inspection and Data Collection

A simple process helps workers find valve problems fast. Sunlike Machinery says to start with a close look and gather key data. Workers should do these steps:

-

Look at the valve and nearby area. Check for damage, leaks, or odd sounds.

-

Measure pressure on both sides of the valve. This shows if the valve works right.

-

Measure how much air goes through the valve. This checks if the valve gives enough air.

-

Do a test to see how the valve moves when the signal changes.

These steps help workers find problems early. Sunlike’s smart sensors and monitors make collecting data easy and correct. Workers use these tools to record pressure, flow, and movement as it happens. This gives a clear view of how the pneumatic valves work.

Tip: Checking valves often and collecting data helps stop surprise breakdowns and keeps production lines moving well.

Using Sunlike’s Tools for Diagnosis

Sunlike Machinery gives special tools that make troubleshooting easy for everyone. Workers use wireless sensors, Bluetooth, and custom apps to check valve health. These tools guide users step by step and show clear results.

-

Wireless sensors check pressure and vibration. They send data to a main system for review.

-

Bluetooth lets workers connect to the valve and see live data.

-

The Stonel Wireless Link app helps users set up tests and see results on phones.

Sunlike’s tools work with all pneumatic valves. They help workers find leaks, stiction, and actuator problems quickly. The tools also let experts help from far away. This saves time and means fewer trips to the site.

Interpreting Results and Implementing Solutions

After getting data, workers need to know what it means. Sunlike’s systems give easy instructions and clear messages. The table below shows steps for reading results and fixing problems:

|

Step |

Description |

|---|---|

|

1 |

Use the reader for quick test instructions or job aids. |

|

2 |

Follow extra instructions like videos and pictures of results. |

|

3 |

Make sure the test is placed right and has enough light. |

|

4 |

Read basic result words like positive, negative, or invalid. |

|

5 |

Check extra messages for help or other resources. |

|

6 |

Use the timer to know when to read the test, following the right time for each test. |

Once workers know the results, they can fix the problems. Common fixes are tightening loose parts to stop noise and shaking, changing airflow, and adding pneumatic mufflers. For harder problems, workers use advanced tools like thermal imaging to find heat and stress in solenoid valves. Predictive tech helps watch valve patterns and plan repairs before things get worse.

Note: Sunlike Machinery’s team gives expert help and resources to guide workers. Their worldwide experience and certified products give good solutions for every need.

www.cn-sunlike.com

Nantong Sunlike Machinery Co., Ltd.

Average Rating