How To Choose The Right Fiber Discs To Achieve The Best Grinding Performance

https://www.goldenabrasives.com/Fiber-disc

Fiber discs are essential tools for precision grinding, sanding, and polishing in a wide range of industries, from automotive to metalworking. Among the various options available, fiber discs are often favored for their durability, versatility, and effectiveness in demanding applications. Choosing the right fiber disc material can significantly impact the quality of your work, as well as the efficiency and longevity of the disc. This article Golden Abrasives will explore three primary types of fiber discs: aluminum oxide fiber discs, zirconia fiber discs, and ceramic fiber discs, and guide how to select the best option for your grinding needs.

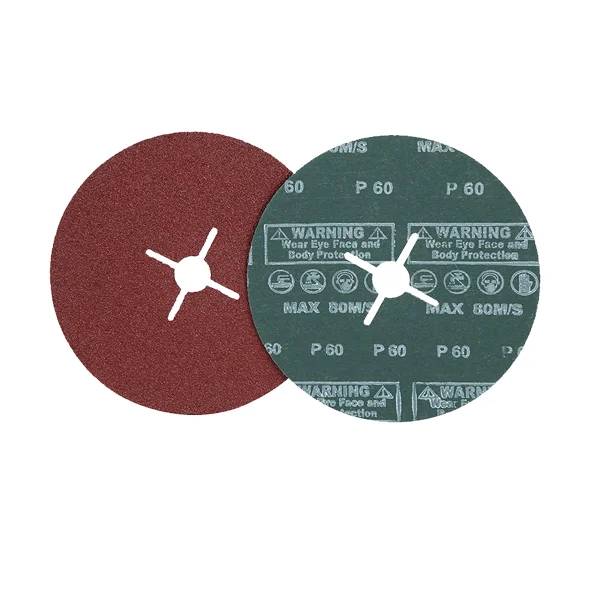

Aluminum Oxide Fiber Discs: General-Purpose Durability and Efficiency

Aluminum oxide fiber discs are among the most widely used abrasives, offering an excellent balance of cost-effectiveness and durability for general-purpose grinding. These discs feature aluminum oxide as the abrasive, which is well-suited for a range of materials, including steel, non-ferrous metals, and plastics.

Aluminum oxide fiber discs are among the most widely used abrasives, offering an excellent balance of cost-effectiveness and durability for general-purpose grinding. These discs feature aluminum oxide as the abrasive, which is well-suited for a range of materials, including steel, non-ferrous metals, and plastics.

Golden Abrasives aluminum oxide fiber discs are designed with a high-strength vulcanized fiber backing and resin-over-resin bonding. This construction ensures reliable durability and performance, even under high-pressure conditions. The aluminum oxide grains provide consistent and efficient grinding, making them ideal for general tasks that require good performance and cost control.

While they excel in standard grinding applications, aluminum oxide fiber discs may not be the best choice for extremely hard materials like stainless steel or high-tensile alloys. However, for softer metals or typical grinding tasks, they offer a solid balance of performance and value.

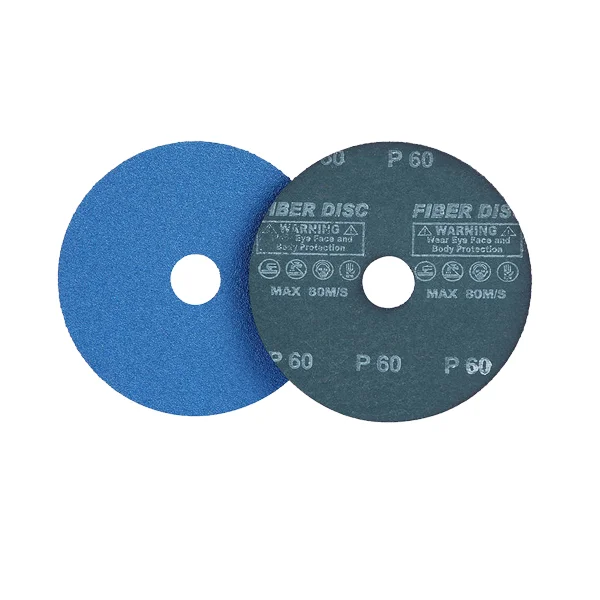

Zirconia Fiber Discs: High-Performance Grinding for Tough Materials

For tougher grinding applications involving high-strength metals, zirconia fiber discs are the ideal choice. Zirconia abrasives are known for their self-sharpening properties, making them particularly effective when grinding harder materials, such as stainless steel and high-alloy metals.

For tougher grinding applications involving high-strength metals, zirconia fiber discs are the ideal choice. Zirconia abrasives are known for their self-sharpening properties, making them particularly effective when grinding harder materials, such as stainless steel and high-alloy metals.

Like the aluminum oxide fiber discs, Golden Abrasives zirconia fiber discs feature a strong vulcanized fiber backing and resin-over-resin bonding. The zirconia grains provide a self-sharpening action, maintaining cutting efficiency over time even as the disc wears. This results in faster material removal, making zirconia fiber discs perfect for industries that require continuous grinding, such as automotive and aerospace.

Zirconia fiber discs also offer exceptional heat resistance, crucial for tasks that generate high levels of friction and heat, ensuring both durability and high performance throughout the grinding process.

Ceramic Fiber Discs: Superior Durability and Precision for Demanding Applications

For the most challenging applications requiring both high material removal rates and fine finishes, ceramic fiber discs stand out. Ceramic abrasives are designed for self-sharpening action, offering superior cutting efficiency, particularly on high-alloy steels and superalloys.

For the most challenging applications requiring both high material removal rates and fine finishes, ceramic fiber discs stand out. Ceramic abrasives are designed for self-sharpening action, offering superior cutting efficiency, particularly on high-alloy steels and superalloys.

Golden Abrasives ceramic fiber discs also use the same vulcanized fiber backing and resin-over-resin bonding as the aluminum oxide and zirconia discs. The advanced ceramic abrasive grains deliver consistent, fast cutting, and are perfect for applications such as weld blending, surface finishing, and removing material from hard-to-grind surfaces.

These discs provide not only high material removal rates but also exceptional durability, maintaining performance throughout the process. Ceramic fiber discs are designed to meet the demands of high-precision tasks that require both efficiency and a smooth finish, making them ideal for industries like manufacturing and aerospace.

How To Choose The Right Fiber Discs For your Grinding Needs

When choosing the right fiber disc for your grinding tasks, several important factors must be considered to ensure the best performance and results. These factors directly affect the efficiency, durability, and overall outcome of your grinding process. Here's a guide on how to make the right choice:

1. Grinding Speed and Efficiency

The speed at which material is removed during grinding is one of the most important factors. Whether you're using aluminum oxide fiber discs, which are well-suited for general-purpose grinding, or opting for zirconia fiber discs for tougher, high-performance tasks, the disc you choose should provide fast and efficient material removal. For precision grinding where rapid material removal is essential, ceramic fiber discs are an excellent choice, as they offer exceptional cutting power and maintain high efficiency throughout their use.

The best fiber discs maintain consistent cutting power as they wear down, ensuring minimal performance degradation and optimal grinding results throughout their lifespan.

2. Durability

Durability is key when selecting a fiber disc, especially for tasks that involve intense or prolonged use. Zirconia fiber discs are known for their durability in high-pressure grinding applications, providing excellent resistance to wear and tear, making them perfect for more demanding environments. Ceramic fiber discs, on the other hand, are specifically designed to last longer under tough conditions and are ideal for precision work that requires both durability and fast material removal.

For less demanding tasks, aluminum oxide fiber discs offer a good balance between durability and cost-effectiveness, making them ideal for standard grinding jobs that don't require as much resistance to wear and heat.

3. Heat Resistance

Grinding generates heat, and the fiber disc material must be able to withstand this heat to maintain its cutting efficiency. Zirconia fiber discs excel in heat resistance, which is crucial when working with metals that generate high temperatures during grinding. Ceramic fiber discs offer superior heat resistance, ensuring consistent performance even under extreme conditions. In contrast, aluminum oxide fiber discs may show reduced cutting effectiveness when exposed to prolonged heat, especially in high-pressure or heavy-duty applications.

For tasks that require sustained performance under heat, zirconia or ceramic fiber discs are often the better choice.

4. Finish Quality

For tasks requiring a smooth and high-quality finish, the choice of fiber disc is critical. Ceramic fiber discs are highly recommended for precision grinding tasks like weld blending, surface finishing, and material removal on hard-to-grind materials, where achieving a consistent and smooth finish is crucial. Aluminum oxide fiber discs, while effective for general grinding, may not deliver the same level of fine finishes that ceramic discs can achieve.

However, if you're working on less demanding applications, aluminum oxide fiber discs will suffice for tasks that don't require the highest quality finishes but still need reliable and efficient results.

5. Cost-Effectiveness

While aluminum oxide fiber discs are the most cost-effective option, especially for general-purpose grinding and light to moderate tasks, both zirconia and ceramic fiber discs come with a higher price tag due to their enhanced performance, durability, and precision. However, these higher-cost discs often prove to be more cost-effective in the long run for demanding applications, as they last longer, provide faster material removal, and reduce the need for frequent replacements.

If you're looking for a disc that offers a good balance between cost and performance, aluminum oxide fiber discs may be the best choice for basic tasks. But for more advanced grinding applications, the initial investment in zirconia or ceramic fiber discs can pay off by delivering higher efficiency and longer-lasting results.

Conclusion

In conclusion, selecting the right fiber disc for your grinding tasks is crucial for achieving optimal performance, efficiency, and cost-effectiveness. Whether you are working with softer materials or tackling tough, high-alloy steels, understanding the specific strengths and applications of aluminum oxide, zirconia, and ceramic fiber discs will help you make the best choice for your needs. Aluminum oxide fiber discs offer great value for general-purpose tasks, while zirconia and ceramic fiber discs provide superior performance, durability, and precision for more demanding applications. By carefully considering factors such as grinding speed, durability, heat resistance, finish quality, and cost-effectiveness, you can ensure that you select the fiber disc that delivers the best results for your specific grinding requirements.

www.goldenabrasives.com

China Golden Abrasives

Average Rating