Mechanisms of Damping Deadening Rubber Sheets: How They Reduce Vibration and Noise

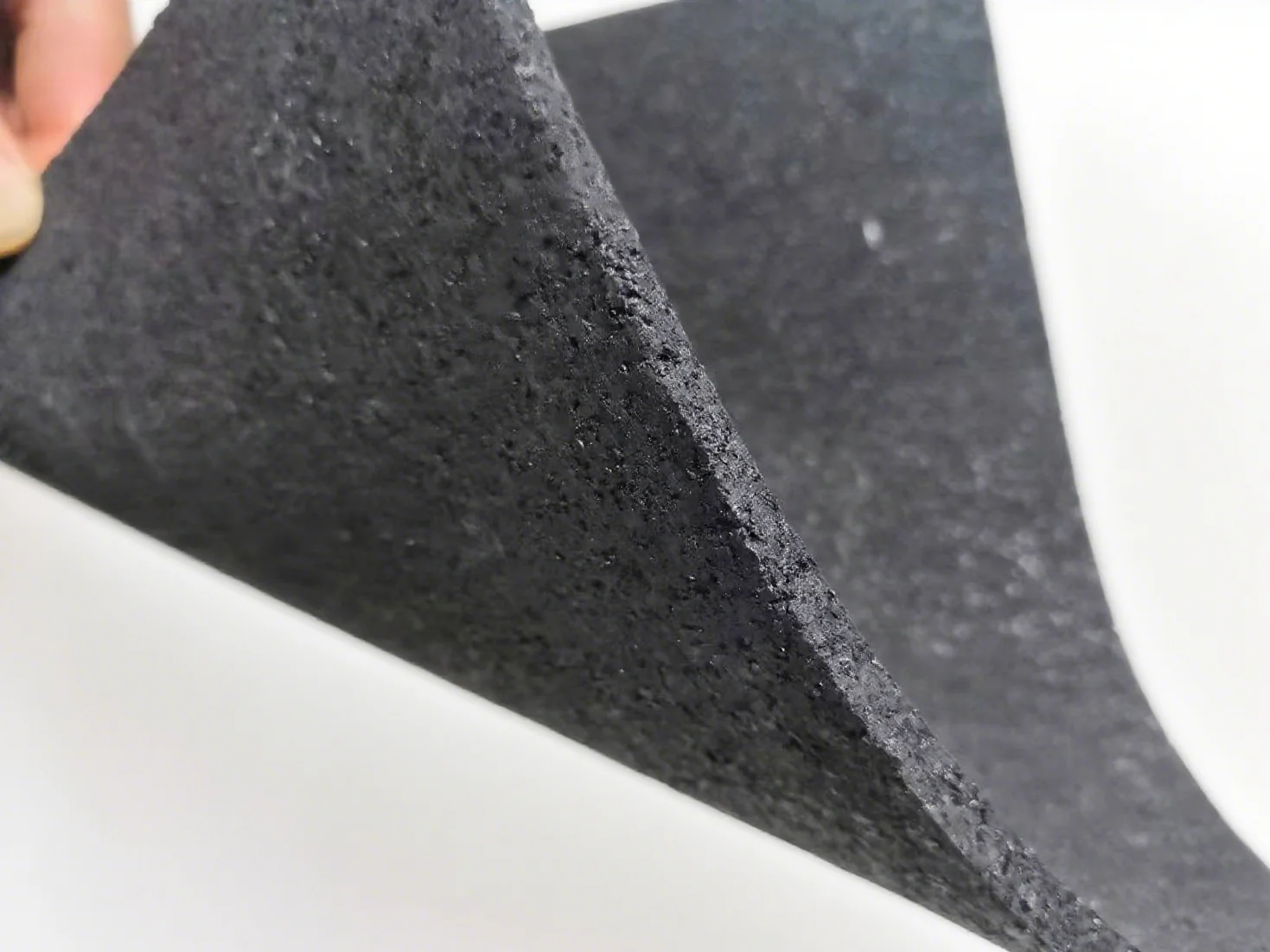

Damping deadening rubber sheets are advanced materials specifically designed to reduce vibration and noise. The primary effectiveness of damping deadening rubber sheets lies in their unique viscoelastic properties, which allow them to absorb energy and dampen vibrations in structures and machinery.

Vibration Energy Dissipation

The main mechanism of damping deadening rubber sheets is vibration energy dissipation. When a structure vibrates, the damping deadening rubber sheets deform microscopically, converting kinetic energy into heat through internal friction. This energy conversion reduces the vibration amplitude and prevents resonance, making damping deadening rubber sheets ideal for automotive, industrial, and construction applications.

Viscoelastic Material Behavior

Damping deadening rubber sheets rely on viscoelasticity, combining both elastic and viscous behavior. Elasticity allows temporary energy storage, while viscosity converts energy into heat. This dual mechanism is the key reason damping deadening rubber sheets efficiently reduce vibration and structural oscillations.

Sound Wave Interruption

Noise reduction in damping deadening rubber sheets is achieved through sound wave absorption and reflection. As sound waves travel through solids, damping deadening rubber sheets disrupt the path of vibrations, lowering both airborne and structure-borne noise levels.

Vibration Path Control

Another critical mechanism of damping deadening rubber sheets is controlling the vibration transmission path. Strategic placement of the sheets at contact points maximizes energy dissipation and prevents vibrations from reaching sensitive areas. Proper contact surface design enhances the performance of damping deadening rubber sheets in real-world applications.

The mechanisms behind damping deadening rubber sheets—vibration energy dissipation, viscoelastic behavior, sound wave interruption, and vibration path control—make them a reliable solution for vibration and noise control. By understanding these mechanisms, engineers can optimize the use of damping deadening rubber sheets in automotive, industrial, and construction projects.

Hyderman Rubber & Plastic Co., Ltd. specializes in manufacturing high-quality damping deadening rubber sheets designed to reduce vibration and noise across automotive, industrial, and construction applications. Leveraging advanced viscoelastic materials and precise engineering, Hyderman Rubber provides reliable solutions that efficiently absorb energy, interrupt sound waves, and control vibration paths, ensuring enhanced performance, durability, and comfort in every application.

https://www.hydermanrubber.com/mechanisms-of-damping-deadening-rubber-sheets.html

Hyderman Rubber & Plastic Co., Ltd.

Average Rating