Solving Common Connectivity Issues: Why Your Design Needs a Robust Rectangular Connector

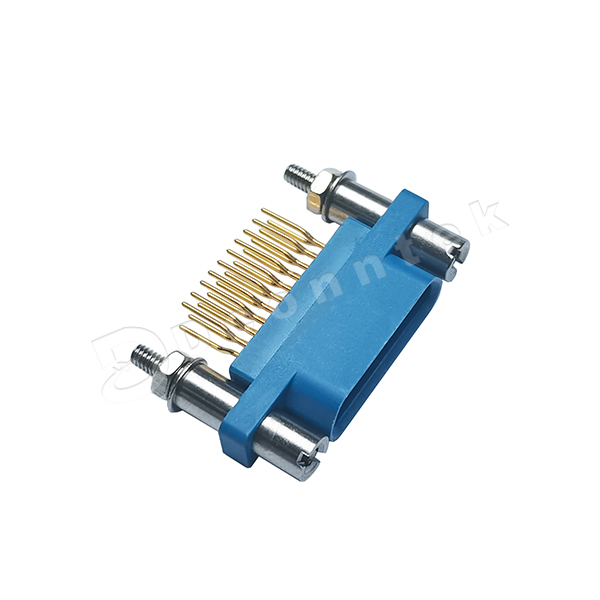

In today’s high-demand engineering environments, connectivity failures can result in costly downtime, lost productivity, and compromised safety. Whether you’re designing industrial machinery, aerospace systems, or transportation equipment, the reliability of your connections is non-negotiable. One solution that stands out in tackling these challenges is the use of robust rectangular connectors.

Understanding Common Connectivity Problems

Connectivity issues can manifest in various ways, including intermittent signal loss, short circuits, or physical disconnections. These problems are particularly prevalent in harsh environments where exposure to vibration, moisture, dust, and temperature extremes can degrade traditional connection methods. For engineers and designers, the challenge lies in ensuring that every connection remains stable throughout the operational lifecycle.

Some typical causes of connectivity issues include:

Environmental stress: Dust, water, and temperature fluctuations can corrode connectors or reduce contact integrity.

Mechanical strain: Vibration, shock, or repeated mating cycles can loosen connections.

Poor design integration: Using connectors not suited to the specific application often leads to premature failures.

Addressing these challenges requires a connector that is not only reliable but also designed for the exact conditions in which it will operate.

Why Rectangular Connectors Are Ideal

Rectangular connectors offer several advantages over other types of connectors, especially in complex engineering applications:

High Contact Density: Rectangular connectors can accommodate multiple pins in a compact footprint, enabling dense wiring configurations without sacrificing performance.

Mechanical Durability: Their robust housing design protects internal contacts from mechanical stress and ensures consistent mating over thousands of cycles.

Environmental Protection: Many rectangular connectors are available with IP-rated seals, offering resistance against dust, water, and other contaminants.

Ease of Maintenance: Standardized form factors make installation and replacement straightforward, reducing downtime during maintenance operations.

For these reasons, rectangular connectors are widely used in aerospace, defense, industrial automation, and transportation applications.

Dconntek’s Role in Custom Connectivity Solutions

When off-the-shelf connectors fail to meet the demands of a specific application, custom engineering solutions become essential. Dconntek is a leading provider of engineered connectors and cable solutions, specializing in harsh environments. By collaborating closely with clients, Dconntek develops customized rectangular connectors tailored to unique operational requirements.

Key Benefits of Partnering with Dconntek

Application-Specific Design: Dconntek engineers work alongside clients to understand environmental conditions, electrical requirements, and mechanical constraints, ensuring the connector performs reliably under real-world conditions.

Rapid Delivery and Prototyping: Leveraging efficient manufacturing processes, Dconntek can produce prototypes and final products quickly, reducing project timelines without compromising quality.

Quality Assurance: Every connector undergoes rigorous testing for durability, conductivity, and environmental resistance, meeting or exceeding industry standards.

Comprehensive Support: From design consultation to post-deployment support, Dconntek provides continuous guidance, ensuring that your connectivity solution remains effective throughout its lifecycle.

By integrating Dconntek’s custom rectangular connectors into a system, engineers can significantly reduce the risk of failures caused by environmental stress or mechanical wear.

Real-World Applications

Industrial Automation

In factories and manufacturing plants, machinery is constantly exposed to vibration, dust, and temperature swings. Rectangular connectors from Dconntek provide reliable electrical and signal connections, ensuring smooth operations for conveyor systems, robotic arms, and automated inspection systems.

Aerospace and Defense

Aerospace applications demand connectors that can withstand extreme temperatures, shock, and high-altitude conditions. Dconntek’s engineered solutions provide secure connections for avionics, communication systems, and control modules, contributing to both safety and mission success.

Transportation

Rail, automotive, and marine systems experience harsh operating conditions, including moisture, salt, and continuous vibration. Custom rectangular connectors ensure uninterrupted power and signal transmission in engines, braking systems, and control units.

Best Practices for Implementing Rectangular Connectors

To maximize the benefits of rectangular connectors and prevent connectivity issues, consider the following best practices:

Match the Connector to the Environment: Use IP-rated or sealed connectors in areas exposed to moisture or dust.

Evaluate Mechanical Stress: Ensure connectors can withstand vibration and shock specific to your application.

Prioritize Contact Materials: Select contact materials with high corrosion resistance and conductivity for long-term performance.

Design for Maintenance: Plan for accessible installation and replacement, reducing downtime.

Partner with Experts: Work with experienced providers like Dconntek to ensure your design meets operational demands and quality standards.

Conclusion

Connectivity is the backbone of modern engineering systems. A single failed connection can compromise performance, safety, and productivity. By choosing robust rectangular connectors and leveraging the expertise of custom solution providers like Dconntek, engineers can mitigate common connectivity issues and ensure long-lasting, reliable performance.

Investing in high-quality, application-specific connectors is not just a design choice—it’s a proactive measure to safeguard the efficiency and safety of your systems. In harsh environments where reliability is critical, robust rectangular connectors are no longer optional; they are essential.

www.dconntek.com

Dconntek

Average Rating