Top Applications of Cylinder Bed Sewing Machines in Footwear, Leather Goods, and Apparel

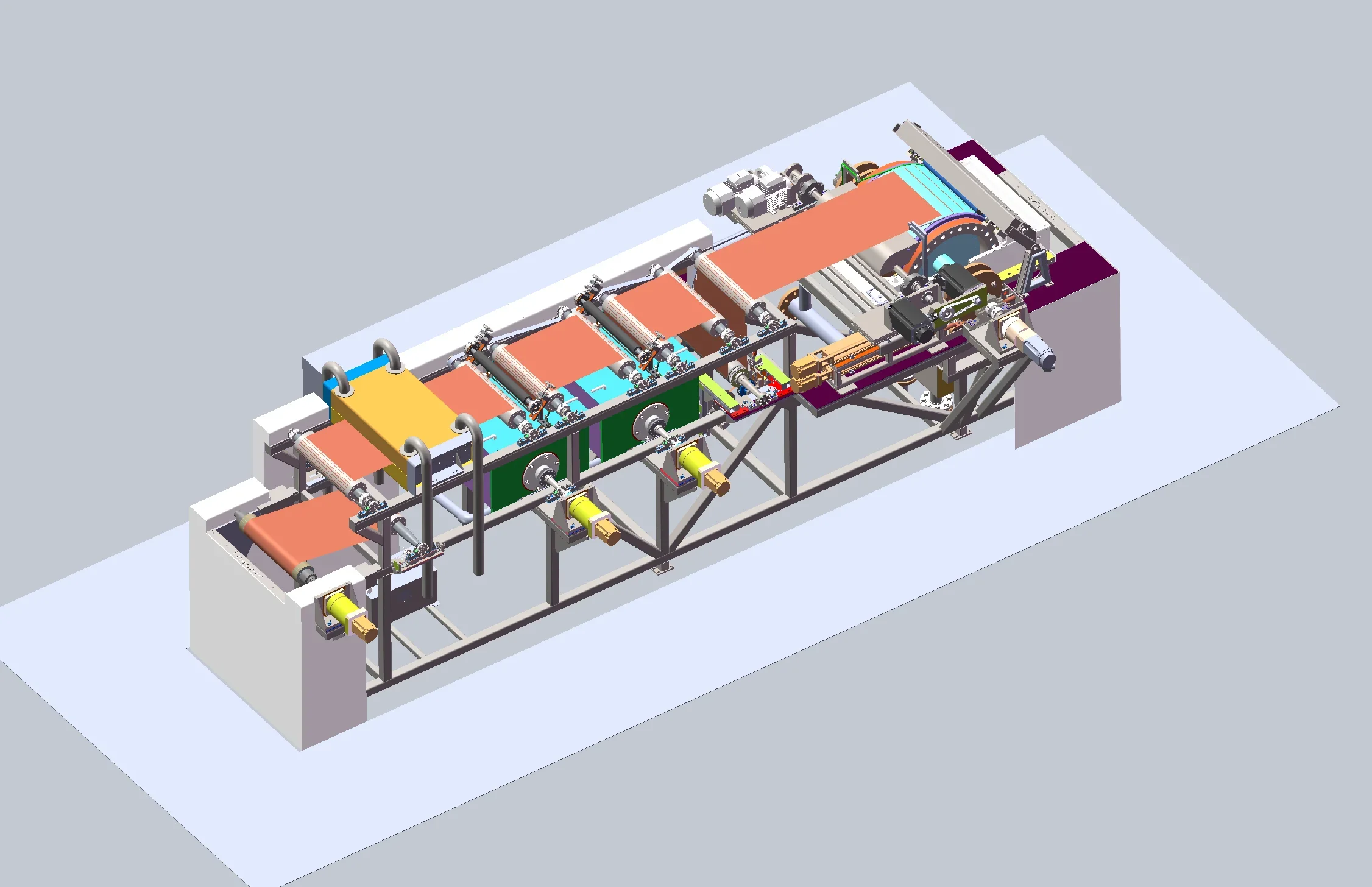

Cylinder bed sewing machines have become indispensable across multiple industries due to their ability to handle complex, three-dimensional stitching tasks with precision and stability. Their narrow, curved sewing platform allows operators to sew tubular, contoured, or hard-to-reach areas that cannot be handled effectively by flatbed machines. As manufacturing demands continue to evolve, advanced equipment from companies like Sanhexin, a professional enterprise specializing in the R&D, production, and manufacturing of sewing machines, is helping brands achieve higher efficiency, finer craftsmanship, and consistent stitching quality.

Below is an in-depth look at how cylinder bed sewing machines are transforming production in footwear, leatherware, and apparel.

Footwear Manufacturing Applications

The footwear industry requires machinery capable of stitching curved surfaces, thick materials, and layered components. Cylinder bed sewing machines excel in these demanding conditions thanks to their ergonomic design and flexible sewing angles.

Sanhexin offers high-precision, durable cylinder bed models featuring strong needle penetration, stable feeding mechanisms, and smooth stitch formation, making them ideal for sewing shoe uppers, heel areas, tongue sections, and decorative edges. Their machines ensure clean stitching even on challenging materials such as leather, suede, and multilayer fabrics.

Leather Goods and Bag Production

Leather products often involve complex shapes and thick structural components. Cylinder bed machines enable precise seam control on items like bags, wallets, belts, and cases, where accuracy and consistency define product quality.

Sanhexin provides robust, high-torque sewing solutions equipped with optimized presser foot systems, enhanced material handling, and refined mechanical balance. These features ensure stable sewing on curved surfaces, helping manufacturers produce premium leather goods with professional finishes and long-term durability.

Apparel and Garment Applications

In the garment industry, cylinder bed sewing machines are commonly used for tubular or circular components that require clean, continuous stitching. This includes sleeves, cuffs, hems, knitwear, and sportswear elements.

Sanhexin’s versatile, smooth-running cylinder bed machines deliver precise stitch control, low vibration, and efficient speed performance, enabling garment makers to achieve high productivity without compromising stitch quality. They are especially valued in activewear and fashion apparel where flexibility and accuracy are crucial.

Upholstery and Thick Material Stitching

Cylinder bed machines are ideal for sewing bulky textiles, soft furnishings, and upholstery components. Their extended reach and curved bed allow operators to maneuver heavy materials with ease.

Sanhexin offers heavy-duty cylinder bed models featuring reinforced frames, strong feeding power, and excellent material compatibility, making them suitable for automotive interiors, furniture upholstery, and outdoor gear production.

Decorative Stitching and Custom Craftsmanship

Cylinder bed sewing machines support intricate decorative work, such as piping, binding, edge stitching, and ornamental seams. Their design allows for detailed control when working on curved or shaped pieces.

Sanhexin integrates advanced mechanical engineering, smooth stitch adjustment systems, and refined tension control, enabling artisans to achieve aesthetic, uniform decorative finishes on both delicate and heavy materials.

Conclusion

Cylinder bed sewing machines play a crucial role in industries that demand precision stitching on complex shapes and high-quality materials. Whether used in footwear manufacturing, leather goods production, or garment assembly, these machines offer unmatched flexibility, accuracy, and efficiency.

As manufacturers seek reliable, high-performance equipment, Sanhexin continues to deliver innovative, stable, and expertly engineered cylinder bed sewing machines that meet the evolving needs of modern production environments. With ongoing technological advancements, cylinder bed solutions will remain essential tools in elevating craftsmanship, productivity, and product quality across global industries.

www.bedoly.net

Ningbo Sanhexin Automation Co., Ltd.

Average Rating