Top Benefits of Using a Fully Automatic Folding Mask Machine in Your Factory

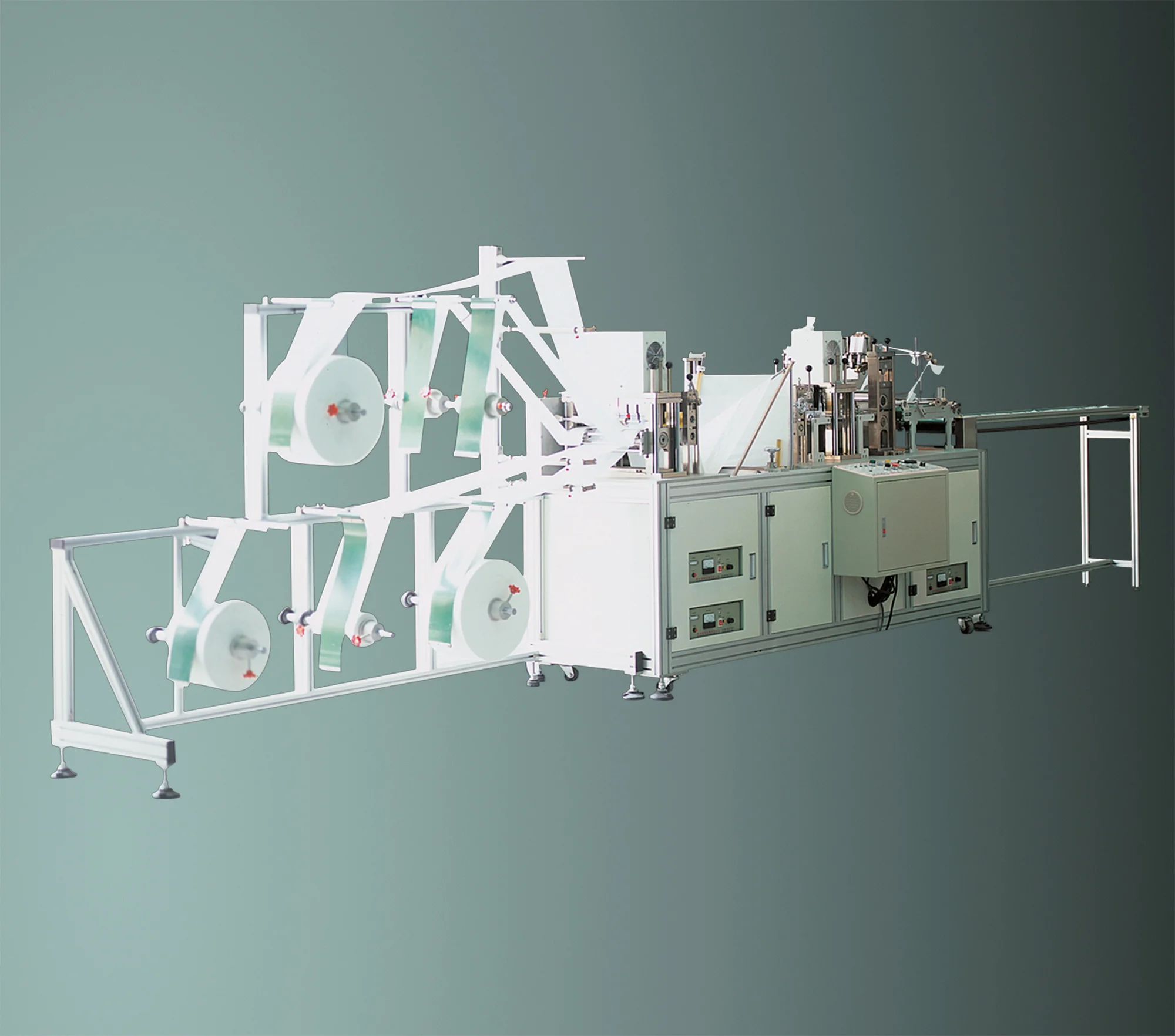

In today’s fast-paced manufacturing environment—especially within the personal protective equipment (PPE) industry—efficiency, reliability, and product quality are essential for staying competitive. A key piece of technology that has transformed mask production is the fully automatic folding mask machine. By automating a complex workflow from raw materials to finished product, this equipment delivers benefits that can dramatically elevate the performance of your factory. In this article, we explore these advantages and highlight how Broadfair Automation Equipment Co., Ltd. delivers high-performance solutions for modern mask manufacturing.

1. Massive Productivity Gains and Labor Savings

A fully automatic folding mask machine takes over repetitive and labor-intensive steps such as material feeding, mask folding, welding, and cutting. These machines run continuously with minimal human involvement, dramatically increasing output while cutting labor costs. With automation handling the majority of production tasks, one operator can often manage what once required many workers—freeing your team to focus on quality control and other value-added functions.

2. Consistent, High-Quality Mask Production

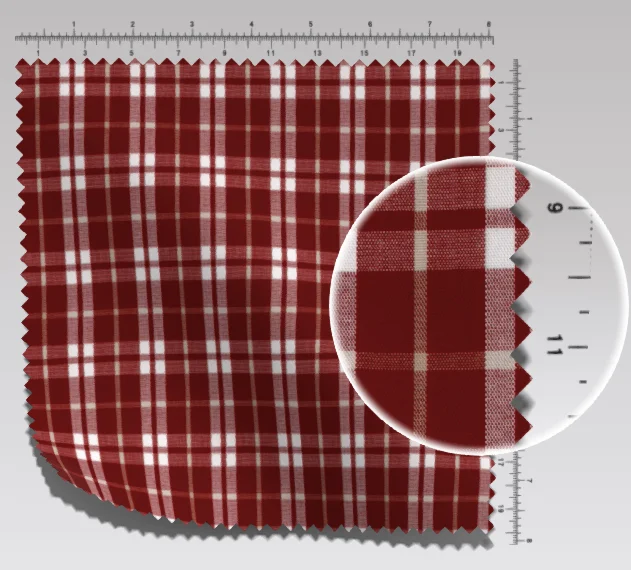

Automatic folding mask machines are engineered to produce masks with uniform size, shape, and structural integrity. Utilizing advanced components like ultrasonic welding and PLC control systems, these machines ensure that folds and welds are precise and secure. This consistency is vital in industries where product quality is not just expected—but mandated by safety standards for surgical, N95, and KN95-style masks.

3. Reduced Error Rates and Waste

Manual processes can introduce variability, misalignment, or defects—leading to waste, rework, and higher manufacturing costs. With automated systems, photoelectric sensors, precise motion controls, and continuous monitoring help eliminate many human errors. As a result, material usage becomes more efficient and overall waste is reduced, translating to lower production costs over time.

4. Improved Workflow and Operational Efficiency

Full automation orchestrates the entire production sequence in a seamless flow—from raw material unwinding to finished mask output. This not only speeds manufacturing but also reduces downtime and streamlines maintenance scheduling. With automatic counting, batch tracking, and integrated fault detection, factories enjoy more predictable and reliable operations.

5. Flexibility to Meet Market Demand

Whether you’re producing flat surgical masks, pleated folding masks, or higher-spec respirators like N95 and KN95, modern folding mask machines can be configured or upgraded to meet different specifications. Molds can be changed, and machine parameters can be adjusted to support a range of mask designs—all without rebuilding your production line from scratch.

6. Enhanced Safety and Hygiene Compliance

Especially in the medical and healthcare sectors, hygiene is paramount. Fully automatic mask machines minimize manual handling of materials, reducing the risk of contamination and helping your products meet strict industry standards. This is particularly important for masks used in clinical, industrial, and public health settings.

7. Partnering with a Proven Automation Supplier

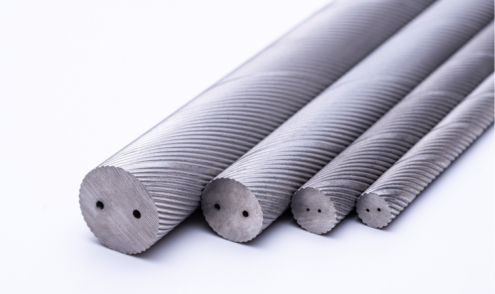

Broadfair Automation Equipment Co., Ltd. is a well-established manufacturer specializing in designing and producing full automated mask machines and non-woven converting equipment. Founded in 2006, the company integrates R&D, production, and sales on a large scale—supported by CNC machining centers, precision tools, and advanced engineering capabilities. Their folding mask machines and other automated solutions enjoy a strong market presence domestically and internationally.

Broadfair’s machines are built for stable performance, ease of operation, and long-term reliability—backed by technical support and a commitment to innovation. Whether your factory is new to mask production or scaling up, partnering with an experienced supplier like Broadfair can help you optimize your automation strategy and stay ahead in a competitive landscape.

Conclusion

Incorporating a fully automatic folding mask machine into your factory isn’t just an upgrade—it’s a strategic investment. From increased productivity and consistent quality to labor savings and compliance with safety standards, the benefits are clear. With trusted automation suppliers like Broadfair Automation Equipment Co., Ltd. providing robust solutions for today’s PPE manufacturers, you’re better positioned to meet current demand and future growth opportunities with confidence.

Choosing the Right Folding Mask Machine : A Buyer’s Guide for Factories

www.broadfairmachine.com

Broadfair Automation Equipment Co., Ltd.

Average Rating