Applications of Automatic Inverted Vertical Wire Drawing Machine

The automatic inverted vertical wire drawing machine has emerged as a crucial tool in modern wire processing industries. With its ability to handle a wide range of wire types and diameters, this specialized equipment combines Italian engineering innovation with tailored solutions for heavy-duty industrial applications. In this blog post, as high performance automatic wire drawing machine exporter, Yifam will share the application of inverted vertical wire drawing machine for sale.

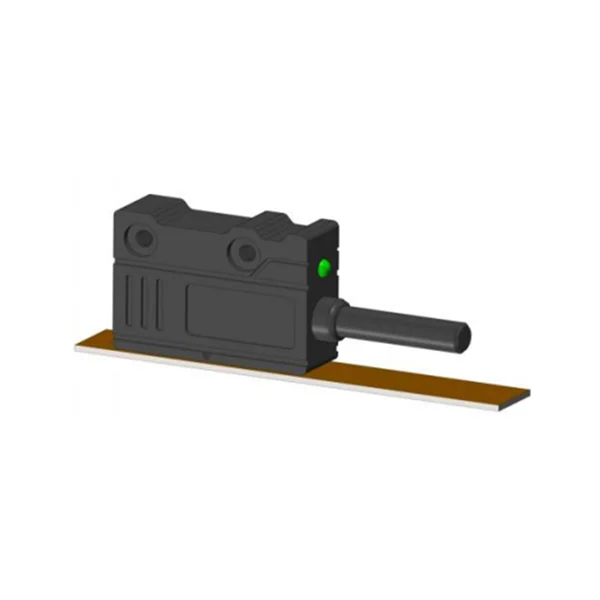

Overview of Inverted Vertical Wire Drawing Machine for sale

The inverted vertical wire drawing machine operates on a non-slipping drawing principle that enables consistent and controlled elongation of high and low carbon steel wires. Unlike conventional horizontal drawing machines, the vertical structure provides better alignment for large diameter wires, significantly improving the drawing accuracy and surface quality.

These machines are specifically engineered for high-strength wire materials and are particularly suitable for industries that demand precision and durability, such as fasteners, springs, and construction wires.

Suitable Materials for Processing

The versatility of the automatic inverted vertical wire drawing machine is demonstrated by its compatibility with a wide range of materials, including:

* Carbon Steels: SAE1010, SAE1018, 10B21, 10B35

* Alloy Steels: EN8D, EN19, EN24, 15B25, 15B41, 1541

* Stainless and Shaped Wires: For applications requiring corrosion resistance and aesthetic appeal

These materials are commonly used in structural, mechanical, and fastener components, making the machine an essential part of their manufacturing processes.

Core Application of Inverted Vertical Wire Drawing Machine

1. Fastener Industry

The fastener industry is one of the primary beneficiaries of this equipment. The inverted drawing machine efficiently processes wire into rods suitable for:

* Bolts and Screws

* Nuts and Studs

* Threaded Rods and Anchor Fasteners

Its ability to maintain precise tolerances and produce smooth surface finishes is critical for downstream forming operations like heading, threading, and heat treatment.

2. Spring and Mattress Wire Production

High-tensile spring wire, commonly used in mattresses and automotive components, requires uniform stress distribution. The vertical drawing machine allows:

* Reduction of wire diameter with minimal mechanical stress

* Consistent wire tension, improving spring life cycle

* Adaptability for different coil sizes and tensile strengths

This consistency is essential in applications such as bedding springs, suspension systems, and mechanical recoil springs.

3. Building and Construction Wire

The machine is widely used to produce wire types necessary for the construction industry, including:

* Rebar tie wire

* Nail wire

* Binding and fencing wire

These wires need high ductility and tensile strength, which are ensured by the machine' s non-slip mechanism and precise drawing controls.

Technical Advantages of Inverted Vertical Wire Drawing Machine

1. Large Plate and Large Diameter Capability

One of the distinctive features of the inverted drawing machine is its ability to accommodate large plate sizes and draw large diameter wires. This is particularly beneficial for:

* Reducing production cycles by handling more material in one setup

* Simplifying coil handling for heavy wire operations

* Increasing productivity in bulk manufacturing environments

2. Non-Slip Drawing System

The non-sliding drawing mechanism ensures:

* Consistent tension throughout the wire length

* Reduced wire breakage and surface flaws

* Improved product quality for further cold heading or forming processes

3. Automation and Operator Safety

Automation is integrated into the system to allow for:

* Reduced manual intervention and labor costs

* Real-time monitoring of drawing parameters

* Enhanced operator safety with interlocks and overload protection

These features are critical in maintaining efficiency while complying with modern industrial safety standards.

Industry Use Cases of Inverted Vertical Wire Drawing Machine

1. Standard Parts Manufacturing

Manufacturers of standard mechanical parts—like washers, pins, rivets, and threaded components—rely heavily on precise wire preparation. The inverted wire drawing machine allows:

* Continuous and uniform output

* Customizable wire dimensions for diverse product lines

* Better compatibility with CNC forming machines

2. Retail Fixture and Supermarket Shelf Industry

Wire products used in retail displays and supermarket shelving require precise shaping and high surface quality. The machine supports:

* Drawing shaped wires (e.g., square, oval)

* Smooth wire surfaces suitable for coating or chrome plating

* Easy adjustment for different profiles and materials

Conclusion

The automatic inverted vertical wire drawing machine is a high-performance, versatile solution designed for the needs of modern wire processing industries. Whether in fastener production, spring manufacturing, or construction wire preparation, this machine offers unmatched efficiency, reliability, and safety. With its advanced technology and robust construction, it supports manufacturers in achieving high-volume output with consistent quality, making it a valuable asset in today's competitive manufacturing landscape.

www.yifam.com

Yifam

Average Rating