Automatic Pipeline Powder Coating Equipment for Manufacturing

Pipeline powder coating equipment has become a cornerstone of advanced surface-finishing technology across metalworking, home appliances, automotive, construction hardware, and industrial machinery. As manufacturers pursue higher efficiency, stable coating performance, and environmentally responsible production, automated powder-coating systems deliver a reliable and high-quality solution that meets stringent global standards. In this blog post, Lexuan Intelligent Equipment, as industrial powder coating production line supplier, will share the principles of automatic pipeline powder coating equipment for manufacturing, its pre-treatment steps, advantages, etc.

How Automatic Pipeline Powder Coating Equipment Works?

The fundamental operating principle of pipeline powder coating equipment is electrostatic adsorption. Powder particles are electrically charged as they are sprayed, allowing them to strongly adhere to the grounded workpiece surface. Through this physical attraction, the powder forms a uniform layer that melts and cures into a dense, durable coating.

The entire process is executed through an automated pipeline structure—each workpiece moves from pre-treatment through coating and curing without interruption. This high-consistency workflow minimizes human error and ensures repeatable coating quality, even in mass-production environments.

Core Principles of Pipeline Powder Coating Technology

The automatic powder coating system depends on energy-efficient and clean processes:

-

Electrostatic adsorption ensures consistent powder distribution.

-

Automated transfer keeps cycle times predictable.

-

High-temperature curing bonds the powder into a hardened protective layer.

-

Closed-loop powder recovery reduces material loss and improves cost performance.

Together, these mechanisms create a coating that offers excellent adhesion, corrosion resistance, and impact durability—benefits that traditional liquid paint systems often struggle to match.

Pre-Treatment Steps in Automatic Pipeline Powder Coating Lines

Pre-treatment is essential for adhesion, long-term stability, and corrosion resistance. A high-efficiency pipeline powder coating line includes the following steps:

Degreasing for Surface Purification

Oil, fingerprints, and machining residue are completely removed to prevent coating defects.

Multiple Rinsing Cycles

Rinsing flushes away chemical residues from degreasing or surface-conditioning agents.

Surface Conditioning to Improve Adhesion

Activation agents increase surface tension, making it easier for powder particles to bond effectively.

Phosphating for Corrosion Resistance

A uniform inorganic phosphate layer serves as a corrosion-resistant foundation, significantly extending the lifespan of the final coating.

Final Rinsing and Controlled Drying

Residual solution is washed off, and the workpiece is dried to ensure the powder will not clump or blister during spraying.

This structured pre-treatment stage helps the automatic pipeline coating equipment deliver coatings with minimal defects and optimal adherence.

Powder Spraying Stage in Automated Pipeline Coating Lines

Once the workpiece is clean and dry, it enters the spraying cabin.

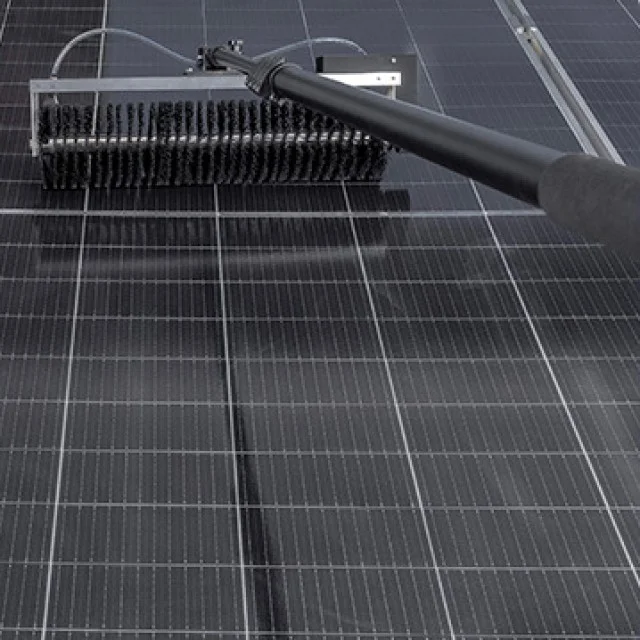

Electrostatic Powder Spraying for Uniform Coverage

Sophisticated electrostatic guns charge powder particles, allowing them to form a consistent coat around complex geometries. Automatic reciprocator machines adjust their movement to match different product shapes, ensuring even distribution.

Manual Touch-Up for Complex Components

Even in highly automated systems, some recessed or intricate areas require manual correction. Trained operators apply small supplemental sprays to achieve total coverage without over-application.

This combination of automation and controlled manual refinement ensures that pipeline powder coating systems maintain exceptional coating consistency.

Curing Process in Pipeline Powder Coating Equipment

The curing stage determines the final mechanical properties, smoothness, and durability of the coating.

High-Temperature Baking for Coating Formation

Inside the curing oven, the powder melts and chemically cross-links into a robust, solid finish. Temperature and conveyor speed are precisely controlled to match the type of powder coating used.

Stabilized Cooling for Optimal Performance

After curing, the workpiece cools naturally or through forced air, ensuring the coating fully stabilizes without deformation or discoloration.

Well-controlled curing is essential for achieving a finish that resists abrasion, chemical exposure, and environmental wear.

Post-Treatment and Quality Control in Pipeline Coating Systems

To maintain reliability, automatic pipeline powder coating equipment incorporates strict inspection stages:

Coating Inspection for Consistent Standards

Technicians evaluate film thickness, adhesion quality, smoothness, gloss level, and uniformity. This step ensures each product meets the required industrial or customer-specific specifications.

Touch-Up and Local Repair

Minor defects—such as small gaps, thin areas, or uneven spots—are quickly corrected using supplemental coating techniques.

Protective Packaging for Delivery

Qualified products are packed to prevent surface damage during transportation or storage.

Post-treatment completes the closed-loop workflow and secures the long-term performance of the coated workpiece.

Key Advantages of Automatic Pipeline Powder Coating Technology

Automatic powder coating lines deliver several critical benefits:

High Efficiency and Material Savings

-

Automated conveyance and spraying significantly reduce cycle times.

-

Powder recovery systems improve material utilization rates and minimize waste.

Environmentally Friendly Operation

Powder coating emits no VOCs, making it a clean alternative to traditional solvent-based paints. It also complies with increasingly strict environmental regulations worldwide.

Superior Coating Quality

The final film exhibits:

-

Strong adhesion

-

Excellent corrosion resistance

-

High wear resistance

-

Uniform surface finish without sagging or runs

These features make automated pipeline systems ideal for demanding industrial environments.

High Degree of Automation

Sensors, programmable controls, and intelligent spraying ensure consistent production with minimal labor input. This reduces operator fatigue and enhances production accuracy.

Strong Adaptability Across Industries

Automatic pipeline powder coating equipment works with a wide range of materials and shapes, including:

-

Steel, aluminum, and alloy parts

-

Plastic housings

-

Furniture frames

-

Mechanical components

-

Pipelines and industrial enclosures

This versatility makes it a preferred choice for manufacturers with diverse production needs.

Applications of Automatic Pipeline Powder Coating Equipment

Industries benefiting from automated powder coating include:

-

Automotive parts manufacturing

-

Household appliance production

-

Architectural aluminum profiles

-

Industrial machinery and equipment

-

Furniture and shelving systems

-

Metal doors, frames, and fences

Because of its consistent quality and low environmental impact, this technology continues to expand into new sectors every year.

Why Manufacturers Choose Pipeline Powder Coating Systems

Modern production demands cost efficiency, stability, and sustainability. Automatic pipeline powder coating equipment delivers these core values by:

-

Reducing rework and defect rates

-

Achieving uniform finish regardless of batch size

-

Minimizing environmental burdens

-

Lowering long-term operating costs

-

Integrating easily with smart-factory platforms

By combining automation with advanced electrostatic coating principles, manufacturers gain a reliable and scalable finishing solution.

Conclusion

Automatic pipeline powder coating equipment is reshaping how industries protect and decorate their products. Its stable performance, environmental advantages, and high production efficiency make it an indispensable part of modern manufacturing. As automation and digitalization continue to advance, these coating systems will further evolve—delivering higher precision, lower energy consumption, and smarter process control.

Whether for mass automotive production or precision industrial components, the automatic pipeline powder coating system provides a clean, durable, and cost-effective solution that supports the long-term competitiveness of manufacturers worldwide.

www.lexuaneqpt.com

Lexuan Intelligent Equipment

Average Rating