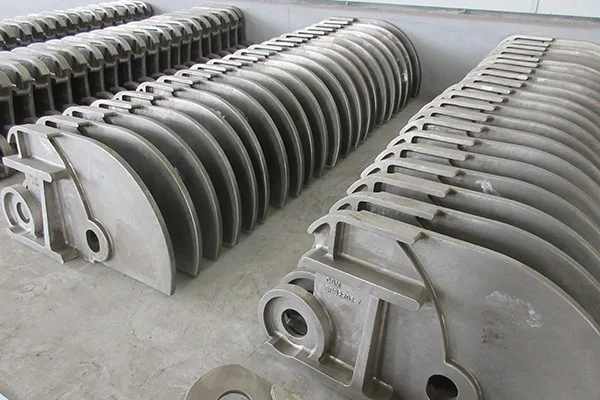

Chain Grating Machine Grate Side Plate: A Complete Guide for Industrial Operations

In heavy industries such as metallurgy, cement, mining, construction materials, ceramics, forging, shipbuilding, and chemical production, chain grating machines play a pivotal role in material handling, drying, and processing. A key component of these machines is the grate side plate, which supports the chains and bears heavy mechanical stress during operation. Proper understanding, selection, and maintenance of the grate side plate are essential for maximizing operational efficiency and extending the lifespan of the machine.

China Special Metal Group Limited (CSM), a leading supplier of high-quality cast steel components, precision-machined products, and welded assemblies, emphasizes the importance of durable and reliable grate side plates for industrial machinery. Their products cater to the demanding conditions of metallurgical, mining, and chemical industries, ensuring high performance and longevity.

1. Understanding the Grate Side Plate

The grate side plate is a structural component that supports the moving chain and distributes load evenly along the chain grating machine. It must withstand:

-

Mechanical stress from moving material and chain operation.

-

Abrasion and wear caused by heavy or abrasive materials.

-

Thermal stress from high-temperature operations, especially in dryers or kilns.

CSM manufactures cast steel grate side plates using high-grade materials and precision machining techniques, ensuring strength, dimensional accuracy, and wear resistance to meet industrial demands.

2. Key Functions of the Grate Side Plate

The grate side plate plays several essential roles in the machine:

-

Structural Support – It maintains chain alignment and supports the weight of conveyed materials.

-

Load Distribution – Ensures even load transfer along the chain to prevent localized stress and potential deformation.

-

Wear Resistance – Protects the machine’s frame from excessive abrasion due to continuous material flow.

-

Operational Stability – Helps minimize vibrations and noise, promoting smooth and efficient chain operation.

By providing these functions, a high-quality grate side plate reduces downtime, improves safety, and enhances overall operational efficiency.

3. Materials and Construction

Grate side plates must be constructed from durable, wear-resistant materials. CSM produces these plates using:

-

High-strength cast steel – To resist heavy mechanical loads.

-

Precision machining – Ensures proper chain alignment and minimal friction.

-

Welded reinforcements – Enhances durability and structural integrity.

The combination of advanced metallurgy and machining technology enables CSM’s grate side plates to handle abrasive and high-temperature industrial environments without compromising performance.

4. Maintenance Best Practices

Proper maintenance is critical to extending the lifespan of the grate side plate. Key practices include:

a. Regular Cleaning

-

Remove debris, dust, and residues that accumulate on the grate side plate.

-

Prevent abrasive materials from accelerating wear.

b. Inspection for Wear and Damage

-

Check for cracks, corrosion, or warping caused by mechanical stress.

-

Monitor wear patterns along the plate to detect early signs of fatigue.

c. Lubrication of Adjacent Components

-

Keep chains, sprockets, and moving parts properly lubricated.

-

Reduce friction and prevent accelerated wear on the side plate.

d. Proper Load Management

-

Avoid exceeding the machine’s designed capacity.

-

Excessive load can bend or deform the side plate and cause misalignment.

e. Timely Replacement

-

Replace worn or damaged plates promptly to prevent secondary damage to the machine.

-

Use high-quality replacements, such as those offered by CSM, to ensure continued operational efficiency.

5. Signs That Your Grate Side Plate Needs Attention

Operators should look out for these signs:

-

Uneven wear or grooves on the plate surface

-

Loose bolts or misalignment of the chain

-

Excessive vibration or noise during operation

-

Cracks, warping, or thinning of the side plate

Early detection and corrective action can prevent costly downtime and extend the life of the chain grating machine.

6. Choosing the Right Grate Side Plate

Selecting a high-quality grate side plate involves considering:

-

Material durability – Must resist wear, impact, and thermal stress.

-

Dimensional accuracy – Ensures proper chain alignment and reduces operational friction.

-

Compatibility – Must fit your specific chain grating machine model and operational environment.

-

Supplier reliability – Choose a trusted manufacturer with experience in industrial machinery components.

China Special Metal Group Limited (CSM) is a reliable partner in this regard, providing cast steel plates and precision-machined components engineered for demanding industrial conditions. Their products are used widely in metallurgical, cement, mining, and chemical industries worldwide.

7. Benefits of Using CSM Grate Side Plates

By using CSM’s high-quality grate side plates, industries can achieve:

-

Extended component lifespan – Reduced wear and fewer replacements.

-

Improved operational efficiency – Smooth chain movement and load distribution.

-

Reduced downtime – High durability minimizes unexpected failures.

-

Cost savings – Less frequent maintenance and part replacement lower operational costs.

CSM’s expertise in cast steel and precision machining ensures that every plate meets strict quality standards and can withstand harsh industrial conditions.

Conclusion

The grate side plate is a critical component in the chain grating machine, directly affecting operational stability, efficiency, and machine longevity. Proper understanding, maintenance, and selection of high-quality materials are essential for industrial operations.

China Special Metal Group Limited (CSM) offers reliable cast steel grate side plates and precision components designed for demanding environments in metallurgy, cement, mining, ceramics, forging, shipbuilding, and chemical industries. By investing in quality components and implementing proper maintenance practices, industries can optimize performance, reduce downtime, and ensure long-term operational success.

www.special-metal.com

China Special Metal Group Limited (CSM)

Average Rating