Customizing Valve Interlocking Systems for Unique Industrial Applications

In today's highly regulated industrial environments, safety, efficiency, and operational reliability are paramount. Valve interlocking systems play a crucial role in achieving these goals, ensuring that valves are operated safely and in the correct sequence to prevent accidents, equipment damage, or operational downtime. While standard valve interlocking solutions are available, many industrial applications require customized systems tailored to unique operational needs. This is where professional companies like Nudango excel, providing bespoke solutions that meet both domestic and international standards.

Understanding Valve Interlocking Systems

Valve interlocking systems are safety mechanisms designed to control the operation of valves in complex industrial processes. These systems ensure that valves can only be operated in a predetermined sequence, preventing dangerous errors such as opening or closing the wrong valve at the wrong time. The main types of valve interlocking systems include:

-

Mechanical Interlocks: Physically prevent valves from being operated out of sequence.

-

Trapped Key Interlocking: Uses keys to enforce sequential operation, ensuring that one action must be completed before another can occur.

By implementing these systems, industries can minimize human error, protect personnel, and avoid costly equipment failures.

Why Customization Matters

While many industries can use standard valve interlocking solutions, unique industrial applications often present challenges that require customization:

-

Complex Piping Networks: Large petrochemical plants, power stations, and steel mills often have highly intricate piping layouts. Standard interlocks may not fit seamlessly into these configurations.

-

Specific Safety Protocols: Different industries and even different facilities within the same sector may have unique safety procedures and compliance requirements.

-

Operational Efficiency: Some operations demand rapid valve sequences that standard systems cannot handle effectively without modification.

-

Integration with Existing Systems: Many industrial sites have legacy systems that require interlocks to integrate seamlessly with SCADA, PLCs, or remote monitoring tools.

Customizing valve interlocking systems allows engineers to address these challenges while ensuring safety, efficiency, and compliance.

Nudango: Expertise in Customized Solutions

Nudango is a professional company renowned for its expertise in designing, manufacturing, and servicing safety products, including valve interlocking systems. The company has passed multiple international certifications, such as CE and HSE, ensuring that its products meet the highest safety and quality standards.

The company's product line includes:

-

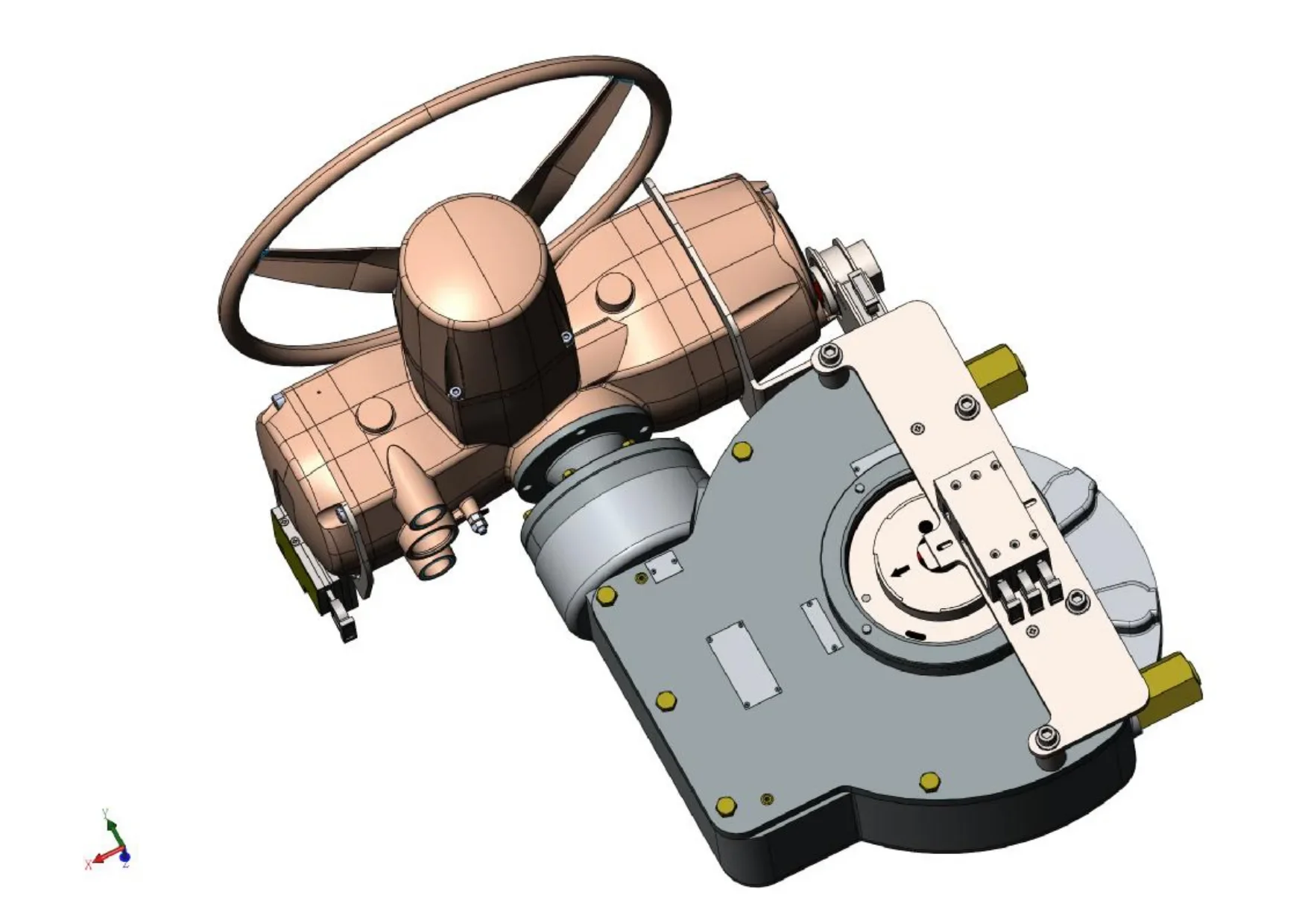

Valve Interlock Systems

-

Trapped Key Interlocking

-

Remote Valve Actuators

-

Portable Valve Actuators

-

Valve Position Indicators

These systems have been widely adopted across industries such as petrochemical, electric power, steel, shipbuilding, and ocean engineering, both domestically and internationally. Nudango has earned a stellar reputation in the industry for providing reliable, safe, and tailored solutions that meet the specific needs of each client.

Steps to Customize Valve Interlocking Systems

When customizing valve interlocking systems for unique industrial applications, a systematic approach is crucial:

1. Conduct a Comprehensive Site Assessment

Understanding the operational environment is the first step. This includes mapping out the piping networks, evaluating the types of valves, and identifying potential safety hazards. By thoroughly analyzing the site, engineers can design interlocks that fit seamlessly into the existing infrastructure.

2. Identify Safety and Compliance Requirements

Different industries have specific regulatory requirements. For example, petrochemical plants must adhere to stringent process safety standards, while shipbuilding operations may need interlocks certified for marine conditions. Customization ensures that the system complies with all relevant CE, HSE, and local regulatory standards.

3. Choose the Appropriate Interlock Type

Depending on the operational complexity and safety requirements, engineers select the most suitable interlocking mechanism:

-

Mechanical Interlocks for simple, robust control.

-

Trapped Key Systems to enforce strict operational sequences.

-

Remote Valve Actuators for large-scale or inaccessible valve networks.

In many cases, a combination of these systems provides the optimal balance of safety, efficiency, and flexibility.

4. Integrate with Existing Systems

Modern industrial operations often rely on SCADA or PLC systems for remote monitoring and control. Custom valve interlocks can be integrated with these systems to provide real-time status updates, operational feedback, and automated safety responses.

5. Testing and Validation

After installation, rigorous testing ensures that the customized interlock system performs as intended under all operational conditions. This includes simulating emergency scenarios and verifying that the system prevents unsafe valve operations.

6. Training and Documentation

Even the best interlock system requires proper training for operators. Nudango provides comprehensive training and documentation, ensuring that personnel understand the operational sequences, maintenance procedures, and emergency protocols.

Benefits of Customized Valve Interlocking Systems

Investing in customized valve interlocking systems offers several advantages:

-

Enhanced Safety: Customized solutions address specific hazards unique to the facility, reducing the risk of accidents.

-

Operational Efficiency: Tailored interlocks streamline valve operations, minimizing delays and downtime.

-

Regulatory Compliance: Systems are designed to meet both local and international safety standards.

-

Reduced Maintenance Costs: Custom-fit systems reduce wear and tear and are easier to maintain.

-

Scalability: Systems can be designed to accommodate future expansions or modifications in the facility.

By tailoring the interlocking system to the facility's exact needs, companies achieve a safer and more efficient operation.

Industry Applications

Petrochemical Industry

In petrochemical plants, valve interlocks prevent unsafe sequences during chemical processing, protecting both personnel and expensive equipment. Custom systems handle complex valve arrangements, emergency shutdowns, and hazardous chemical flows.

Electric Power Plants

Valve interlocks in power generation facilities manage cooling water, steam, and fuel systems. Customized solutions ensure that critical valves operate in the correct sequence during startup, operation, and emergency shutdowns.

Steel Manufacturing

Steel mills have intricate piping and fluid systems for cooling and chemical treatment. Custom valve interlocks prevent operational mistakes that could damage equipment or halt production.

Shipbuilding and Ocean Engineering

Marine environments require interlocks that withstand harsh conditions such as saltwater corrosion and vibration. Customized systems ensure operational safety for valves controlling ballast, fuel, and hydraulic systems on ships and offshore platforms.

Conclusion

Customizing valve interlocking systems is no longer a luxury but a necessity for industries with complex operational environments. Companies like Nudango demonstrate the value of tailored solutions, combining professional design, high-quality manufacturing, and comprehensive service to meet the unique safety and operational needs of diverse industrial applications. By investing in customized valve interlocks, industries not only enhance safety and efficiency but also ensure regulatory compliance and long-term operational reliability.

In a world where operational errors can have severe consequences, tailored valve interlocking systems are a strategic investment that safeguards personnel, protects assets, and ensures smooth industrial operations

www.nudango.com

nudango

Average Rating