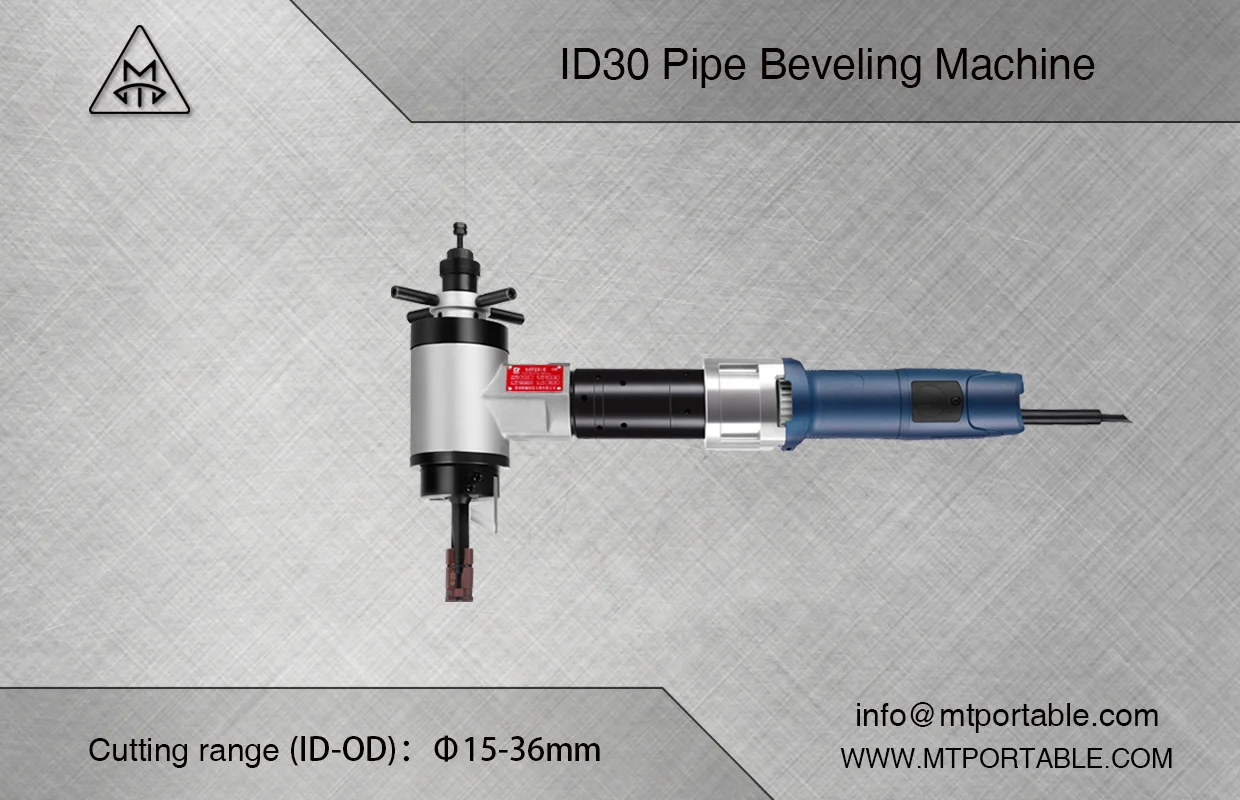

ID30 Pipe Beveling Machine – Compact and Powerful Weld Preparation Tool

ID30 Pipe Beveling Machine – Compact and Powerful Weld Preparation Tool

Product Overview

The ID30 Pipe Beveling Machine is a robust, high-speed, and portable ID-mounted lathe engineered for precision weld end preparation. Designed for cutting and beveling pipes and tubes made from carbon steel, stainless steel, and high-chromium alloys, it is ideal for applications in power generation, process industries, and tube and pipe manufacturing. With its cold-cutting operation, the ID30 ensures high-quality bevels without thermal distortion, making it a reliable choice for field or workshop use.

Key Features

1. Cold Cutting Technology: Avoids heat-affected zones (HAZ), ensuring superior weld integrity.

2. Versatile Material Compatibility: Suitable for carbon steel, stainless steel, and alloy tubes.

3. Multi-Function Capability: Capable of beveling, counterboring, and J-prepping.

4. Compact and Lightweight: Self-centering design, easy to install and operate in tight spaces.

5. Flexible Drive Options: Available in electric (MT and Bosch) and pneumatic models to suit various job site conditions.

Model and Drive type:

IDE30 Pipe Beveling Machine

MT Electric motor (1.21 Hp / 0.9 Kw), 220-240 V, 50/60 Hz

IDB30 Pipe Beveling Machine

Bosch Electric motor (1.34 Hp / 1.0 Kw), 220-240 V, 50/60 Hz

IDP30 Pipe Beveling Machine

Pneumatic motor (1.34 Hp / 1.0 Kw), 1.3 m³/min @ 0.6 Mpa

Cutting & Mounting Capacity

Cutting Range (ID–OD): 15 – 36 mm (0.59" – 1.42")

ID Mounting Range: 15 – 28 mm (0.59" – 1.10")

Maximum Wall Thickness: ≤ 8 mm (0.31")

Feed Stroke: 25 mm (0.98")

Crate Dimensions (L×W×H): 650 × 500 × 190 mm

Applications

On-site maintenance in power plants and refineries

Tube end preparation for boilers and pressure vessels

Workshop production of pipe spools and fittings

Available Accessories

Tool bits for beveling, facing, and counterboring

For more information or a quotation, contact our technical team at: info@mtportable.com

www.mtportable.com

Jichuang Machinery Manufacturing Wuxi Co.,Ltd

Average Rating