Pallet Packaging System: A Complete Guide to Efficient and Secure Industrial Packaging

In today’s fast-paced manufacturing and logistics environment, efficient and secure packaging is essential for protecting products, reducing costs, and ensuring smooth transportation. As shipment volumes increase and supply chains become more complex, the pallet packaging system has become a cornerstone of modern industrial packaging. From factories and warehouses to export-oriented logistics hubs, pallet-based packaging solutions help businesses achieve consistency, safety, and operational efficiency.

This article provides a comprehensive overview of pallet packaging systems, their key components, benefits, and how automation specialists such as Dostar Packing Equipment Co., Ltd. support advanced industrial packaging needs.

What Is a Pallet Packaging System?

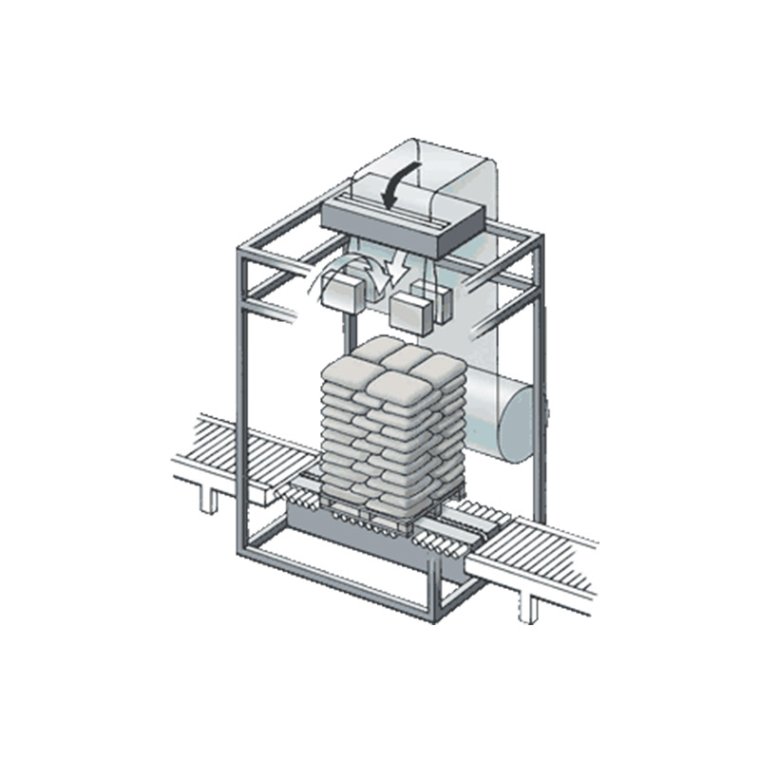

A pallet packaging system is an integrated solution designed to stabilize, protect, and prepare palletized goods for storage and transportation. It typically includes processes such as palletizing, wrapping, strapping, and labeling. By securing products on pallets, companies can streamline handling, reduce damage, and improve loading and unloading efficiency.

Modern pallet packaging systems can be semi-automatic or fully automatic, depending on production volume, labor availability, and operational requirements.

Key Components of a Pallet Packaging System

A complete pallet packaging system usually consists of several core elements working together seamlessly:

Palletizing Equipment

Palletizers arrange products in stable patterns on pallets, ensuring uniform load distribution and consistent stacking.

Stretch Wrapping and Shrink Wrapping Systems

Wrapping systems secure the pallet load, preventing movement and protecting goods from dust, moisture, and impact during transport.

Strapping and Securing Solutions

Strapping adds an extra layer of stability, particularly for heavy or irregular loads.

Conveying and Control Systems

Conveyors and control units connect each stage of the packaging line, enabling smooth, continuous operation with minimal manual intervention.

Benefits of Using a Pallet Packaging System

Improved Packaging Efficiency

By automating repetitive packaging tasks, pallet packaging systems significantly increase throughput and reduce dependence on manual labor.

Enhanced Load Stability and Safety

Consistent wrapping and strapping ensure that products remain secure throughout storage and transportation, reducing the risk of damage and workplace accidents.

Lower Operational Costs

Although the initial investment may be higher, automated pallet packaging systems help reduce long-term labor costs, material waste, and product loss.

Scalability and Flexibility

Pallet packaging systems can be adapted to different product sizes, pallet types, and packaging materials, making them suitable for a wide range of industries.

Semi-Automatic vs. Fully Automatic Pallet Packaging Systems

Choosing between semi-automatic and fully automatic pallet packaging systems depends on production scale and business goals.

Semi-automatic systems are ideal for small to medium-sized operations seeking improved efficiency without significant capital investment. Fully automatic pallet packaging systems, on the other hand, are designed for high-volume production environments where speed, consistency, and minimal human intervention are critical.

Dostar Packing Equipment Co., Ltd., a high-tech enterprise specializing in the research, integration, manufacturing, sales, and service of automated packaging production lines, offers both semi-automatic packaging systems and fully automatic pallet packaging lines to meet diverse customer requirements.

Applications Across Industries

Pallet packaging systems are widely used in industries such as:

-

Manufacturing and industrial goods

-

Food and beverage processing

-

Building materials and chemicals

-

Logistics and warehousing

-

Export and international shipping

Their ability to standardize packaging processes makes them an essential solution for companies operating in competitive and regulated markets.

The Role of Automation and Smart Packaging

With the advancement of industrial automation, pallet packaging systems are becoming increasingly intelligent. Integrated sensors, programmable controls, and data monitoring help optimize packaging performance and reduce downtime.

Dostar Packing Equipment Co., Ltd. continues to focus on providing reliable and efficient automated packaging solutions, helping customers upgrade from manual processes to intelligent, high-performance packaging lines that support long-term growth.

Conclusion

A pallet packaging system is a vital investment for businesses seeking efficient, secure, and scalable industrial packaging solutions. By combining palletizing, wrapping, strapping, and conveying into a cohesive system, companies can improve productivity, protect products, and enhance supply chain reliability.

As a professional provider of automated packaging production lines, Dostar Packing Equipment Co., Ltd. delivers both semi-automatic and fully automatic pallet packaging systems designed to meet the evolving needs of modern manufacturing and logistics operations. Choosing the right pallet packaging system is not just about packaging—it is about building a more efficient and competitive industrial future.

www.dostar-pack.com

Dostar Packing Equipment Co., Ltd

Average Rating