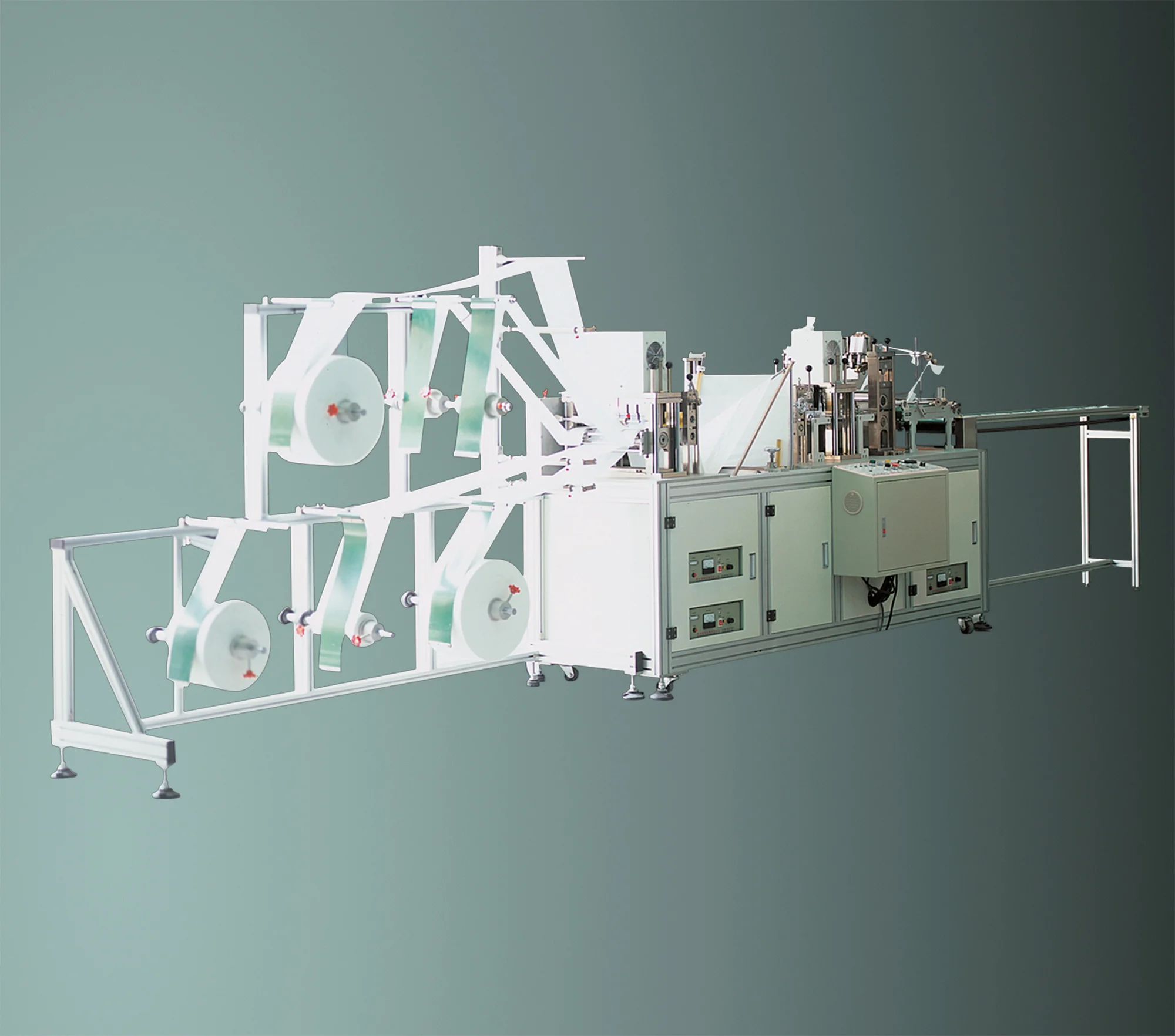

Comprehensive Solutions for Automated Solid Face Mask Production

In the rapidly evolving world of health protection and personal care manufacturing, solid face masks have emerged as a high-demand product. Their consistent shape, precise formulation, and hygienic packaging require advanced automation technology to ensure production efficiency and quality. Broadfair Automation Equipment Co., Ltd., a high-tech enterprise integrating research and development, manufacturing, and sales, is at the forefront of delivering comprehensive solutions for automated solid face mask production.

Through innovation and engineering excellence, Broadfair provides automation systems that streamline every stage of the manufacturing process—from raw material preparation to final packaging—helping manufacturers meet high-quality standards while optimizing output.

Understanding Automated Solid Face Mask Production

Producing solid face masks involves a series of intricate steps that require both precision and consistency. Unlike liquid or sheet masks, solid masks must maintain a uniform shape and density to ensure even application and effectiveness. This process typically includes material blending, heating, forming, cooling, cutting, and packaging—all of which benefit from automation.

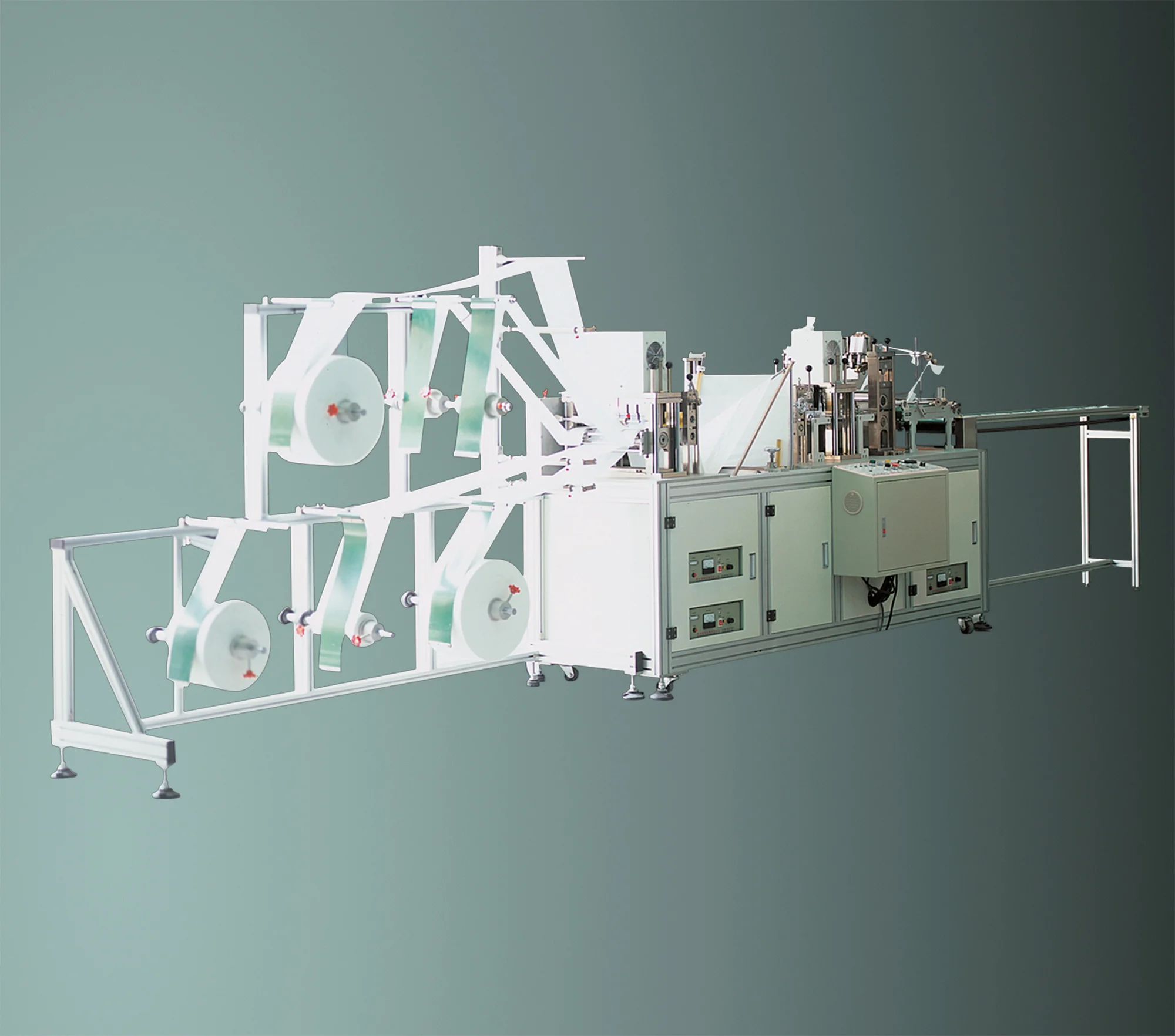

Broadfair’s integrated systems combine mechanical accuracy with intelligent control to minimize manual intervention. The result is a cleaner, more efficient production environment that maintains consistent product quality and meets stringent hygiene requirements.

Key Components of an Integrated Automation System

An automated production line for solid face masks consists of several interdependent modules, each designed for a specific stage of manufacturing. Broadfair designs these modules to operate seamlessly together for optimal performance.

Material Preparation and Mixing: Automated feeders and mixers ensure precise material ratios and homogeneous blending, a critical step for achieving consistent mask quality.

Forming and Molding: Advanced temperature and pressure control systems guarantee accurate shaping and structural stability.

Cutting and Finishing: High-precision cutters and sensors maintain uniform dimensions, minimizing waste.

Packaging and Labeling: Fully automated packaging solutions increase throughput while ensuring cleanliness and product protection.

By integrating these processes, Broadfair enables manufacturers to maintain production speed without compromising product integrity.

Ensuring Quality and Hygiene in Every Step

In personal care product manufacturing, hygiene and quality assurance are non-negotiable. Broadfair Automation Equipment Co., Ltd. designs its systems using food-grade stainless steel, enclosed conveying structures, and easy-to-clean surfaces. Automated monitoring and inspection systems detect irregularities in real time, reducing the risk of contamination or defects.

Furthermore, the company’s solutions incorporate data recording and traceability features, allowing manufacturers to maintain complete production records and comply with regulatory requirements.

Enhancing Efficiency Through Intelligent Control

Automation is not merely about replacing manual labor—it’s about intelligent optimization. Broadfair’s production systems are equipped with smart control interfaces, allowing operators to adjust parameters, monitor performance, and analyze production data through user-friendly dashboards.

With integrated PLCs and touch-screen controls, operators can quickly switch between product types, adjust cycle times, or fine-tune temperature and pressure settings. This flexibility enhances operational efficiency and allows rapid adaptation to changing production needs.

Customization and Engineering Expertise

Every manufacturing facility has unique requirements, and Broadfair understands the importance of tailored solutions. Its engineering team collaborates closely with clients to design systems that fit specific space layouts, production capacities, and product formulations.

From concept to commissioning, Broadfair provides full technical support, including installation, training, and maintenance services. This comprehensive approach ensures that each automation system delivers long-term reliability and peak performance.

Commitment to Innovation and Excellence

As a company that integrates R&D, production, and sales, Broadfair Automation Equipment Co., Ltd. continually invests in technological innovation. Its commitment to precision engineering, sustainable design, and intelligent manufacturing helps clients enhance productivity while maintaining environmental responsibility.

Through advanced automation solutions for solid face mask production, Broadfair enables manufacturers to elevate quality, reduce costs, and strengthen competitiveness in the global market.

Conclusion

The demand for solid face masks continues to expand, driving manufacturers to seek more efficient, reliable, and hygienic production methods. With its deep technical expertise and integrated approach, Broadfair Automation Equipment Co., Ltd. stands out as a trusted partner in automated solid face mask production.

By combining innovation, precision, and comprehensive service, Broadfair delivers end-to-end automation solutions that empower manufacturers to achieve excellence in every mask produced.

The Ultimate Guide to Solid Face Mask Making Machines: Functions and Applications

www.broadfairmachine.com

Broadfair Automation Equipment Co., Ltd.

Average Rating