Boost Solar Manufacturing Performance with a High-Efficiency Photovoltaic Panel Production Line

As the global renewable energy market grows at an unprecedented pace, solar power continues to dominate as a clean, efficient, and scalable solution. Behind every high-performance solar module is a reliable and highly automated photovoltaic panel production line that ensures quality, consistency, and manufacturing precision. For solar manufacturers, investing in a modern photovoltaic panel production line is crucial for improving productivity, meeting international standards, and remaining competitive in an increasingly demanding global marketplace. A high-efficiency photovoltaic panel production line integrates advanced automation, process control, intelligent inspection systems, and traceable data management to deliver stable outputs at large-scale capacity. With well-designed production equipment, manufacturers can achieve high throughput while maintaining strict control over quality, performance, and safety parameters throughout the entire production cycle. This directly supports long-term business growth, lowering production costs while increasing customer confidence in the finished solar modules.

Why A Photovoltaic Panel Production Line Matters

In today's rapidly evolving solar manufacturing environment, precision, automation, and process reliability have become the core drivers of success. A high-efficiency photovoltaic panel production line is designed to optimize every stage of module assembly — from individual cell processing to final quality testing — ensuring that each PV module delivers stable electrical performance and long-term durability. By integrating automated handling, intelligent monitoring systems, and strict process-control technology, a modern photovoltaic panel production line significantly reduces human-error risk, improves operational consistency, and enhances manufacturing yield rates.

Beyond improving production accuracy, a high-efficiency photovoltaic panel production line also helps manufacturers lower operational costs and improve return on investment through better energy use, fewer defects, and reduced rework. For companies serving international PV markets, this level of efficiency is critical. A well-engineered photovoltaic panel production line supports compliance with global standards such as IEC, UL, and TUV, meaning the modules produced can be confidently installed in residential rooftops, commercial facilities, utility-scale solar farms, and industrial energy systems across multiple regions. In essence, an optimized photovoltaic panel production line forms the technological backbone of scalable, cost-effective, and globally competitive solar manufacturing.

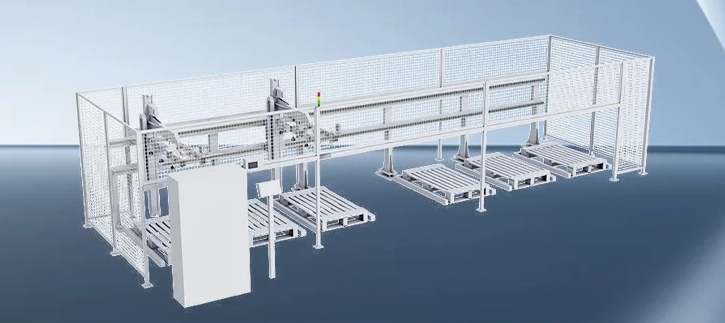

Key Processes in a Photovoltaic Panel Production Line

A modern photovoltaic panel production line consists of multiple interconnected manufacturing stages that must operate in harmony to achieve consistent product quality. Each step — from raw-cell handling to module encapsulation and final inspection — plays a direct role in determining the panel's electrical output, mechanical strength, and long-term performance. When these stages are fully automated and standardized, the photovoltaic panel production line minimizes production errors, material waste, and performance variations between batches.

To further support quality stability, advanced photovoltaic panel production lines incorporate smart-sensor technology and inline inspection systems. These monitor temperature, alignment, pressure, string integrity, lamination sealing quality, and bonding performance throughout the production cycle. Automated handling equipment also reduces physical stress on delicate solar cells, preventing micro-cracks and electrical degradation. As a result, every module leaving the photovoltaic panel production line is manufactured under tightly controlled conditions and meets the required performance benchmarks before shipment.

Cell Sorting & Stringing

The first critical stage in a photovoltaic panel production line is cell sorting and stringing. Solar cells are tested and grouped according to electrical characteristics such as voltage and current output. This ensures that matched cells are assembled together, preventing performance imbalance inside the final module. Automated stringing machines on the photovoltaic panel production line then connect the cells using precision soldering technology designed to optimize conductivity and reduce resistive losses.

High-accuracy soldering is essential for long-term reliability, as poor interconnection can result in hot-spots, reduced output, or early module failure. By using automation rather than manual operation, the photovoltaic panel production line guarantees consistent solder quality across thousands of panels. This creates a stable foundation for electrical performance throughout the lifetime of every solar module produced.

Layup & Positioning

During the layup stage, the photovoltaic panel production line places the connected cell strings onto tempered glass layers together with EVA encapsulant and a protective backsheet. Precision alignment systems ensure that every cell is positioned correctly to prevent shading loss, internal tension, or partial-cell coverage that could negatively impact module efficiency.

Automated layup technology used in a photovoltaic panel production line also helps maintain structural balance and uniform mechanical support. This protects fragile cells from bending stresses and enables the finished modules to withstand environmental exposure such as wind pressure, temperature cycling, and mechanical loading. By reducing manual handling, the photovoltaic panel production line increases both production speed and alignment accuracy while reducing material waste.

EL & Visual Inspection

Electroluminescence (EL) imaging is a vital quality-control step integrated into the photovoltaic panel production line. EL testing exposes otherwise invisible defects such as micro-cracks, broken fingers, and insufficient solder joints. Identifying these issues early prevents defective modules from advancing to later stages, helping to avoid warranty risk and field-performance failures.

When EL testing is combined with automated optical inspection, the photovoltaic panel production line establishes a fully traceable quality-assurance process. This ensures each panel not only meets internal manufacturing standards but also satisfies customer expectations and certification requirements.

Lamination

Lamination is one of the most technically sensitive operations within a photovoltaic panel production line. During this stage, high-temperature and vacuum-pressure conditions permanently bond the module layers to create a sealed, weather-resistant structure. A high-performance laminator ensures full EVA cross-linking, bubble-free encapsulation, and complete environmental sealing to protect the solar cells from moisture, dust, and external contaminants.

Well-controlled lamination on the photovoltaic panel production line directly influences module durability, insulation safety, and long-term outdoor performance. Stable lamination parameters help extend product lifespan and guarantee reliable power output in various climates and installation environments.

Trimming & Framing

After lamination, panels are transferred along the photovoltaic panel production line to trimming and framing stations. Excess laminate material is removed, and structural aluminum frames are installed to reinforce the panel edges. Framing improves mechanical rigidity, provides mounting strength, and helps protect the glass edges against impact or transportation damage.

Automated framing systems in a photovoltaic panel production line deliver consistent dimensional accuracy, ensuring compatibility with mounting structures and simplifying field installation.

Junction Box Installation

The junction box plays a crucial role in power transmission and electrical safety. On a modern photovoltaic panel production line, the junction box is installed using industrial adhesives and sealed to ensure waterproof and electrically insulated operation. Secure connection quality prevents energy loss, overheating, and moisture ingress — all essential for safe long-term use across residential, commercial, and utility-scale PV applications.

Final Testing & Packaging

Before shipment, each panel produced on the photovoltaic panel production line undergoes final testing including IV curve measurement, insulation resistance checks, high-voltage safety validation, and visual inspection. Only modules that successfully pass every test are packaged and sent to market. This helps manufacturers build a strong reputation for reliability while reducing return and warranty cases.

Final Thoughts

A high-efficiency photovoltaic panel production line is not simply a set of machines — it is a complete manufacturing ecosystem that determines the quality, consistency, and competitiveness of solar modules in the global market. By adopting automation, precision engineering, and rigorous quality-control systems, manufacturers can significantly increase output efficiency while reducing operational risks and production costs. In a rapidly expanding renewable-energy industry, an optimized photovoltaic panel production line provides the technological strength needed for sustainable growth and long-term success.

https://www.calowenauto.com/Products

www.calowenauto.com

Calowen

Average Rating