Precision Automobile Steering Gear Technology for Modern Vehicle

A precision automobile steering gear is a core mechanical assembly that ensures a vehicle responds accurately to driver input. As modern mobility trends demand higher stability, comfort, and performance, steering mechanisms have evolved into highly engineered components. The steering gear converts the rotary motion from the steering wheel into the angular displacement needed to turn the wheels, forming the fundamental link between human control and vehicular movement. The precision level of this conversion determines steering accuracy, on-road feedback, and long-term reliability. In this blog post, Longruifa, as one of the high quality custom industrial gear manufacturers, will share the structural design of precision automobile steering gear, its functional role, etc.

Structural Design of Precision Automobile Steering Gear

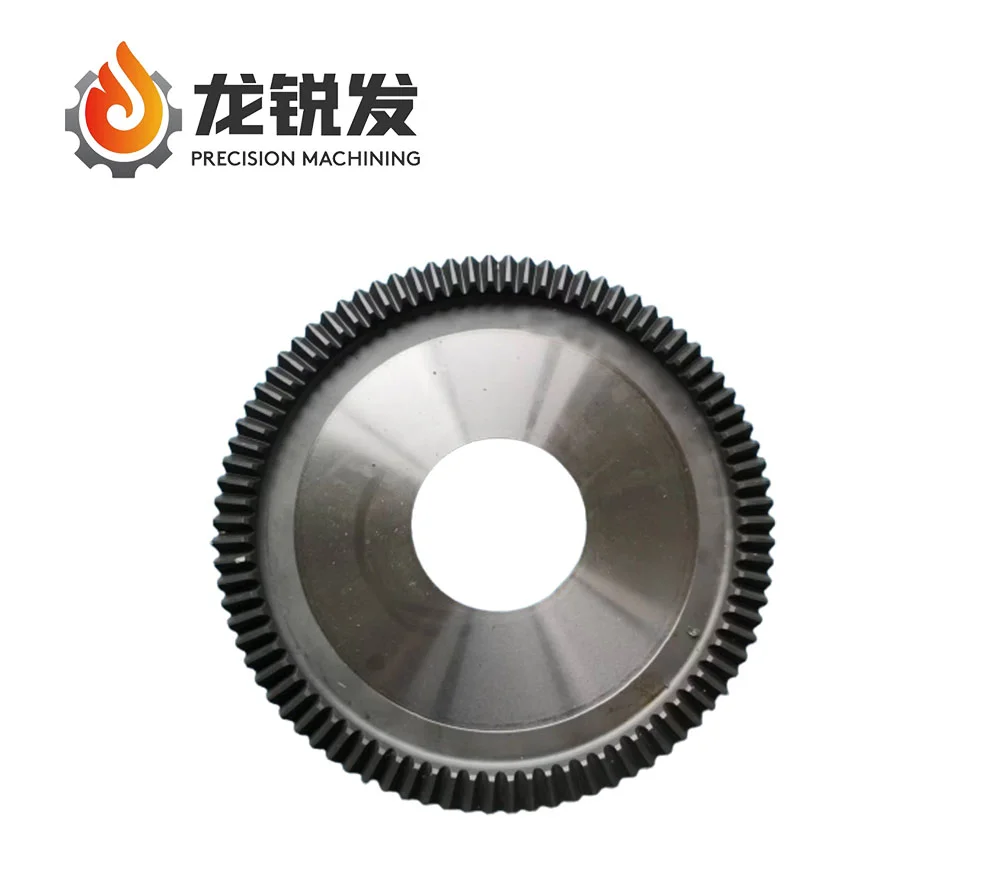

The geometry of a precision steering gear component directly influences its performance. One representative part is a disc-shaped gear featuring regularly spaced spiral teeth along its circumference and a central circular aperture for mounting and alignment. This spiral-tooth structure optimizes torque transfer and ensures smooth meshing with the mating gear elements inside the steering assembly.

High-strength metal alloys are typically selected for such components due to their wear resistance, load-bearing capability, and thermal stability. Precision machining guarantees consistent tooth geometry, minimal backlash, and balanced rotational behavior. These design attributes collectively support stability during cornering, vibration suppression, and extended service life, even under demanding road conditions.

Functional Role of Precision Steering Gear Components in Vehicles

Within the vehicle’s steering architecture, precision automotive gear components transmit steering force through the interaction of paired gear profiles. As the steering wheel rotates, torque is delivered through the shaft to the gear interface. The spiral teeth engage smoothly with connecting elements—often a worm gear, pinion, or rack segment—converting rotational input into controlled angular motion.

This mechanical transformation ensures that steering adjustments remain proportional and predictable. The precision of gear meshing directly affects steering sensitivity, lane-keeping accuracy, and safety at higher speeds. In high-performance automotive platforms, exact tooth alignment is essential to achieve responsive handling without sacrificing stability or driver confidence.

Material Engineering in Precision Automobile Steering Gear Manufacturing

Material engineering plays a crucial role in the manufacturing of precision automobile steering gear mechanisms. Industrial designers prioritize metals with high tensile strength and fatigue resistance to withstand continuous oscillating loads. Heat treatment processes enhance hardness and reduce deformation during prolonged operation.

Advanced machining technologies—such as multi-axis CNC systems, gear hobbing, and surface grinding—are used to achieve micrometer-level accuracy. The fine tolerances ensure consistent tooth engagement and reduced noise during gear operation. Protective coatings may also be applied to minimize corrosion, extend durability, and maintain mechanical integrity in varying environmental conditions.

Gear Geometry and Transmission Efficiency in Vehicle Steering Systems

The geometric profile of a precision vehicle steering gear influences both efficiency and steering feel. Spiral or helical teeth distribute load across multiple contact points, lowering stress concentrations and improving torque transmission. This geometry allows smoother rotation compared to straight-cut profiles, contributing to quieter steering operation and reduced friction.

Optimized tooth angles, pitch dimensions, and contact patterns prevent slippage during sudden steering maneuvers. These parameters are carefully calculated during design to achieve a balance between strength, smoothness, and responsiveness. The result is a gear system that reacts fluidly to driver commands while maintaining directional stability.

Integration of Precision Steering Gear Within Automotive Assemblies

Integration within the broader steering assembly is critical for system performance. A precision steering gearbox is continuously interacting with linkages, bearings, housings, and input shafts. The disc-shaped spiral-tooth component plays a central role in synchronizing the mechanical motion of these elements.

Accurate positioning during assembly ensures optimal contact between mating gears. Lubrication channels are often engineered into the housing to maintain consistent oil distribution, reducing wear and thermal buildup. Proper integration ensures that steering dynamics remain stable across different vehicle speeds, load conditions, and driving environments.

Performance Advantages of Precision Automotive Steering Gear Systems

Precision-engineered steering gear mechanisms offer several performance advantages:

-

Higher steering accuracy: Minimal backlash ensures immediate response to driver input.

-

Improved stability: Even torque distribution enhances control during cornering and emergency maneuvers.

-

Reduced operational noise: Precision tooth surfaces and smooth meshing lower acoustic output.

-

Extended service life: Durable alloy materials and optimized tooth geometry reduce wear.

-

Greater driving comfort: Smooth transitions and consistent feedback create a premium steering feel.

These benefits are particularly valuable in modern passenger vehicles, electric cars, autonomous platforms, and performance-oriented automotive applications.

Application Scope of Precision Steering Gear in Modern Vehicles

A precision automobile steering mechanism is used across a wide range of vehicle types. In compact cars, accurate steering improves drivability in narrow urban environments. For electric vehicles, predictable steering response contributes to energy-efficient operation and software-based driving assistance systems.

Commercial trucks and off-road vehicles rely on robust gear structures capable of handling high torque loads. Performance cars benefit from tight steering tolerances that allow quick directional changes at elevated speeds. Across all applications, precision gears ensure consistency between driver intention and vehicle behavior.

Comparison Between Precision Steering Gear Designs

Different steering gear designs are chosen based on vehicle requirements:

-

Rack-and-pinion systems: Common in passenger cars, offering direct steering feel and lightweight construction.

-

Worm-and-roller systems: Suitable for heavy-duty vehicles requiring high torque and durability.

-

Electric power steering gears: Integrate sensors, electric motors, and precision gears for adaptive steering control.

Precision gear components—such as the spiral-tooth disc gear described—can be customized to suit any of these systems. Material composition, tooth geometry, and mounting structure are adjusted to match torque requirements, steering feedback expectations, and vehicle size.

Quality Control in Precision Automobile Steering Gear Production

Quality assurance is fundamental in producing precision steering gear components. Manufacturers employ coordinate-measuring machines (CMM), optical scanning, tooth-profile testing, and endurance trials to ensure that each gear meets engineering standards.

Dimension checks confirm concentricity, aperture size, tooth pitch, and surface finish. Load simulations test the gear’s ability to withstand real-world steering forces. These strict procedures guarantee uniformity across batches and prevent deviations that could affect safety or steering performance.

Future Trends in Precision Steering Gear Technology

Automotive steering technology is evolving with digitalization and automation. Future precision automobile gear assemblies may integrate:

-

Smart sensors for real-time condition monitoring

-

Lightweight metallurgical composites

-

Surface-engineered coatings to minimize friction

-

AI-driven predictive maintenance algorithms

-

Enhanced compatibility with autonomous driving platforms

These innovations aim to improve system efficiency while supporting the transition toward intelligent and electrified transportation.

Conclusion

A precision automobile steering gear is far more than a mechanical link—it is a foundational component that defines the driving experience. From its spiral-tooth geometry to its role in torque transmission and vehicular control, it determines how accurately a vehicle responds to human input. Through advanced materials, machining technology, and rigorous quality standards, precision steering gear components ensure safety, comfort, and reliability across all vehicle categories.

As automotive engineering continues to advance, the importance of precisely designed steering mechanisms will only grow, shaping the future of intelligent mobility and high-performance driving.

www.lrfgears.com

Longruifa

Average Rating