Why do automotive transistors fail and how Mengke Electronics helps prevent it

You trust transistor automotive reliability when you start your car. You also trust it when you use safety features. If a transistor automotive part fails, your car may break down. You might also see system errors. Reliability is important because each transistor automotive part helps your car work. Many drivers ask why transistor automotive reliability is not always good. Mengke Electronics gives new ideas to make transistor automotive reliability better. If you know why parts fail, you can help stop active component failures. This helps your car systems work well.

Key Takeaways

-

Knowing why transistors fail, like from too much heat or too much electricity, can help you stop problems in your car.

-

Check often for warning signs, like burn marks or strange actions in your car's electronics, so you can find problems early.

-

Use good ways to keep things cool, like heat sinks and smart board designs, to stop your car's electronics from getting too hot.

-

Make sure all pin connections are tight and clean so you do not get problems from rust or loose parts.

-

Pick good parts from trusted companies like Mengke Electronics to help your car's electronics last longer and work better.

Main Causes of Transistor Automotive Failures

You need to know why electronic parts fail in cars. This helps your car stay reliable. Many drivers and repair workers have these problems. Let’s talk about the main reasons transistors in cars stop working.

Overheating and Thermal Stress

Overheating is a big reason why electronic parts break in cars. If a transistor gets too hot, it can stop working fast. Power inside the transistor makes heat. If heat cannot get out, the part gets even hotter. This can make things worse and cause more damage. Overheating can break the collector junction in bipolar transistors. You might see this when your car’s electronics fail in hot weather or after long trips. Mengke Electronics uses special materials and smart designs to help protect against heat and lower overheating risks.

Electrical Overload and Overvoltage

Electrical overload and overvoltage also cause many failures. Overvoltage happens when voltage goes higher than the transistor can take. Overcurrent means too much current goes through the part. Both can hurt the transistor and make it wear out faster. New cars use more voltage and current, so these problems happen more often. Protection circuits help, but bad design or broken parts can still cause failure. Mengke Electronics adds strong protection to keep these problems away.

-

Common sources of electrical overload and overvoltage include:

-

Sudden power spikes that stress electronics

-

Bad circuit designs that let voltage get too high

-

Parasitic parts that make extra current

-

Local defects that make the transistor weak

Manufacturing Defects and PCB Issues

Mistakes in making parts can cause many failures. Small problems in the transistor or PCB can make current flow unevenly. This makes hot spots and raises the chance of overheating. Even tiny flaws can make the part break early. Mengke Electronics checks quality and tests parts to lower these risks and make sure each part is good.

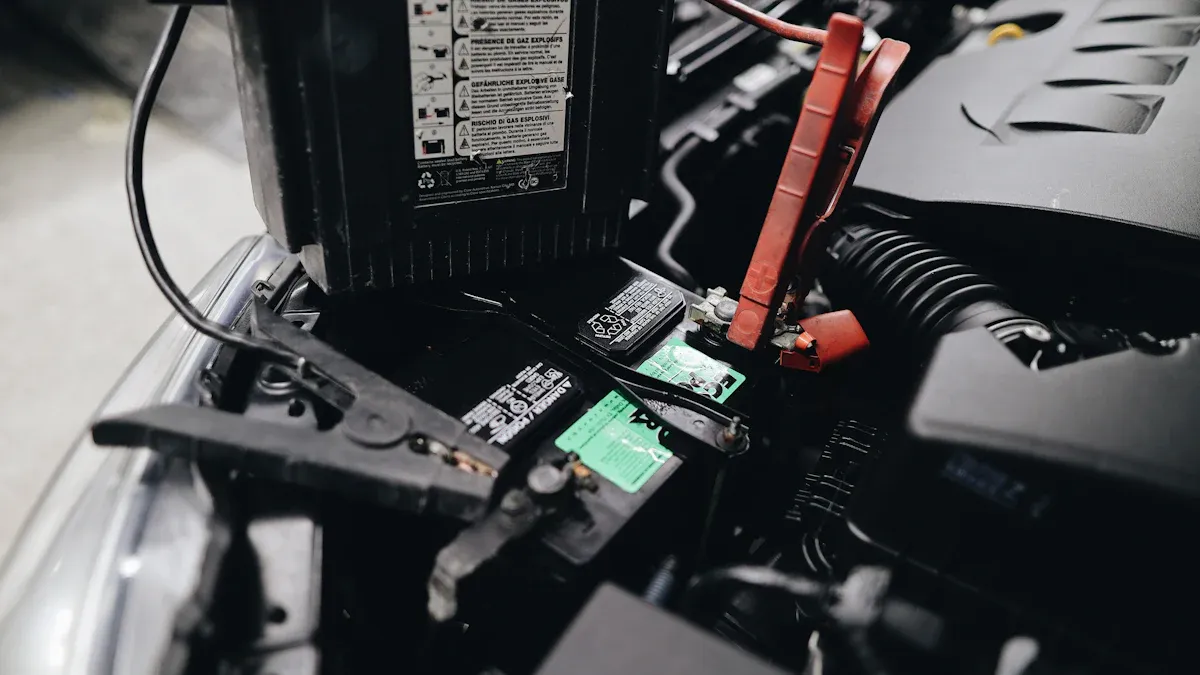

Incorrect Wiring and Pin Connections

Wrong wiring and bad pin connections often cause failures. Things like shaking, water, and heat can make connections loose or rusty. This causes problems that come and go and makes electronics unreliable. You might see voltage drops or strange actions in your car’s electronics.

Here is a table showing typical wiring and pin connection issues:

|

Fault Category |

Common Causes |

Typical Symptoms |

|---|---|---|

|

Connector/pin failure |

Rust, loose pins, bad crimping |

Connections that work sometimes, voltage drops, strange actions |

Mengke Electronics makes parts strong to fight these problems from the environment. This helps you avoid many failures in electronic parts.

Troubleshooting Transistor Failures in Vehicles

Identifying Common Failure Signs

It is important to notice warning signs early. If a circuit does not turn on, something may be wrong. Strange actions in electronics can mean a bad part. Look for electric current that is too high or too low. If a transistor or nearby part gets hot, it may be failing. Dim or blinking LEDs can show trouble. Motors that are weak or sound that is poor can also be clues. Burn marks or broken packaging are clear signs of damage. Wrong voltage readings across the transistor’s terminals mean there is a problem. These clues help you check parts before bigger problems happen.

Diagnostic Steps for Automotive Circuits

You can use simple steps to find transistor failures. First, look for damage like burn marks or cracks. If you see these, act quickly. Next, use a multimeter in diode mode. Put the probes on the transistor’s terminals. Check for the right voltage drop. If you see a short or open circuit, the part is bad. Check other parts for power supply problems. Make sure the input voltage matches the design. If you find a bad transistor, replace it and test the circuit. Use testing methods like checking how the part works and measuring voltage. This helps you make sure the repair is good. Knowing how to test parts helps you stop failures from happening again.

Tip: Always test every part before you use it to make sure it works.

Addressing Overheating and Short Circuits

You need to fix overheating and short circuits fast. Give enough space between hot parts on the PCB. Use thermal vias to move heat away. Add heat sinks and pads to soak up extra heat. Pick materials that move heat well. For parts that get hot easily, use fans for cooling. Always think about things like temperature changes, humidity, and shaking. These steps and testing methods help your electronics work well and lower the chance of failure.

Mengke Electronics gives you strong products and advice for checking parts. Their skill in testing and quality checks helps you fix transistor failures quickly.

How to Prevent Electronic Component Failures

Effective Thermal Management

You can keep your car’s electronics cool by using smart methods. Copper planes and thick traces help heat move away faster. This lowers how much heat builds up by about 30%. Heat sinks and thermal pads pull heat away from hot parts. Fans can blow air to cool things down, especially in electric cars. Good board layouts put parts in the right spots to stop heat from building up. Mengke Electronics uses these ways to stop parts from breaking and make transistors last longer.

-

Copper planes and traces help spread heat.

-

Heat sinks and pads move heat away fast.

-

Fans cool down hot spots.

-

Smart layouts stop heat from building up.

Ensuring Proper Pin Connections

Good pin connections are important to stop failures. You need to check that every connection is tight and clean. This keeps power and signals moving without problems. Strong connections also keep out water and shaking, which can cause rust and damage. The materials, coating, and shape of pins all help make a good connection. Mengke Electronics makes parts that fight off damage from the environment and lower the chance of failure.

-

Tight connections stop signal problems.

-

Good materials and coatings make parts last longer.

-

Pin shape helps keep contact strong.

-

Protection keeps out rust and damage.

Quality Control and Burn-In Testing

Burn-in testing finds weak parts before they go in your car. Workers test parts in tough conditions to see if they break. This helps catch problems in important systems like brakes. Burn-in testing uses high heat and shaking to make sure only strong parts are used. Mengke Electronics checks quality and tests parts to give you reliable transistors and cut down on replacements.

Circuit Design for Preventing Active Component Failures

Smart circuit design helps stop failures. You should check how heat moves and look for weak spots. Fault tree analysis helps you find ways things can break. Put hot parts away from sensitive ones and use heat sinks and thermal vias. Stop EMI by using solid ground planes and short wires. Put heavy parts near mounting holes to stop shaking. Always use the right ratings when you replace parts. Mengke Electronics uses smart designs to lower failures and make transistors work better.

|

Circuit Design Strategy |

Benefit |

|---|---|

|

Thermal analysis |

Stops overheating |

|

Worst-case analysis |

Finds weak spots |

|

Fault tree analysis |

Shows how things can break |

|

EMI control |

Cuts down on interference |

|

Vibration resistance |

Stops damage from shaking |

|

Component derating |

Makes parts last longer |

You can stop electronic part failures by following these steps. Mengke Electronics gives you good products and advice to help you avoid failures and need fewer replacements.

www.jymskj.com

Shenzhen JinyiMingsheng Technology Co., Ltd.

Average Rating