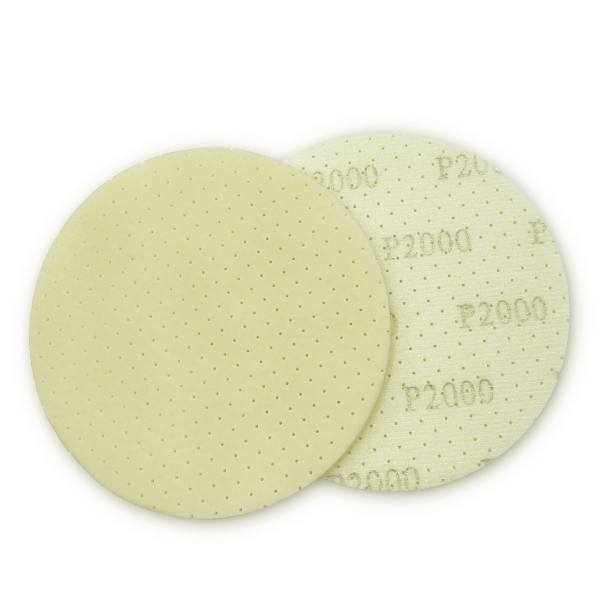

Flexible Foam Disc with Multi Holes: Precision Surface Refinement for Modern Finishing Demands

Author: China Golden Abrasives

Website: www.goldenabrasives.com

Emai: sales@goldenabrasives.com

WhatsApp:+86 13636609141

https://www.goldenabrasives.com/flexible-foam-disc-with-multi-holes.html

In professional surface finishing operations, consistency and control are often more critical than aggressive material removal. When working with curved panels, transitional edges, or surfaces that demand a refined finish, sanding tools must respond predictably to pressure and surface variation. The flexible foam disc with multi holes has been developed to meet these requirements by combining controlled flexibility with stable abrasive performance.

Rather than acting as a rigid cutting tool, this type of disc is designed to adapt to the surface during sanding. Its construction allows it to maintain uniform contact, manage dust effectively, and support repeatable surface refinement across different finishing stages. Understanding how this disc functions in practice helps explain why it is widely used in controlled sanding environments.

Surface Behavior Requirements in Modern Sanding Processes

Modern finishing processes place increasing emphasis on surface uniformity and process stability. Whether preparing a substrate for coating, blending surface transitions, or refining an existing finish, sanding tools must deliver consistent feedback rather than rapid stock removal. Uneven pressure transfer, localized cutting, or abrasive loading can quickly compromise surface quality, especially at finer grit stages.

A flexible foam disc with multi-holes supports these requirements by maintaining stable contact between the abrasive surface and the workpiece. Its controlled flexibility allows it to follow subtle surface contours while moderating pressure changes introduced by hand movement or machine motion. This behavior helps preserve uniform scratch patterns and reduces the risk of surface irregularities during subsequent finishing steps.

Structural Logic Behind Flexible Foam Disc with Multi-Holes

A flexible foam disc with multi-holes is designed around the interaction between three core elements: the abrasive grain, the foam backing, and the hole configuration. Each of these components contributes to the disc’s sanding behavior and surface response during operation.

The foam backing serves as a compressible interface between the abrasive grain and the workpiece. Unlike rigid paper or film backings, foam allows controlled deformation under pressure. This flexibility enables the disc to maintain consistent contact across uneven or contoured surfaces without concentrating force on high points. As a result, sanding pressure is distributed more evenly, reducing the likelihood of surface gouging or irregular scratch patterns.

The multi-hole configuration plays a crucial role in airflow management during sanding. When connected to standard vacuum-assisted sanding systems, these holes allow dust and debris to be evacuated efficiently from the sanding interface. This not only improves visibility for the operator but also prevents abrasive loading, helping the disc maintain cutting consistency throughout its service life.

In professional finishing processes, this structural balance is what makes a flexible foam disc with multi holes particularly effective for controlled material removal and surface refinement.

Flexible Foam Disc with Multi-Holes Functional Interaction

From a structural perspective, a flexible foam disc with multi holes is defined by a set of interrelated parameters that directly influence sanding behavior and surface response. Disc diameter, foam thickness, abrasive grain type, grit range, and hole configuration work together to determine how the disc performs under controlled sanding conditions.

A standard diameter of 150 mm allows the disc to integrate seamlessly with commonly used random orbital sanding systems, ensuring stable rotation and balanced contact across the surface. The 3 mm foam thickness provides sufficient compressibility to adapt to surface variations while maintaining enough structural support to prevent excessive deformation during operation. This balance allows the abrasive layer to remain consistently engaged without collapsing under pressure.

The abrasive grain selection also plays a critical role. Premium aluminum oxide grains offer predictable cutting characteristics and stable edge retention, particularly important in finer grit ranges such as P600 to P2000. At these grit levels, the goal is not material removal speed but controlled surface refinement, where scratch depth and uniformity must remain consistent across the entire work area.

The multi-hole configuration supports this consistency by managing airflow and debris extraction at the sanding interface. Dust is removed before it can accumulate between the abrasive surface and the workpiece, reducing friction and minimizing unintended surface marking. When combined with a soft foam backing, this structure allows the disc to maintain clean, even contact throughout the sanding cycle.

In products such as the Golden Abrasives flexible foam disc with multi holes, these parameters are carefully matched: a soft foam backing paired with premium aluminum oxide grain, a multi-hole layout for effective dust evacuation, and a construction designed to conform to irregular surfaces. This structural coordination supports uniform sanding behavior across materials, including non-ferrous metals, stainless steel, plastics, painted surfaces, glass, and hardwood. In terms of sanding stability and finish consistency, the performance aligns closely with established flexible foam sanding discs available on the market, including comparable solutions from 3M.

Conclusion

The flexible foam disc with multi holes is designed to support controlled, uniform surface refinement rather than aggressive cutting. Through the interaction of foam backing, abrasive grain, and multi-hole dust extraction, it delivers predictable sanding performance across different materials and finishing stages.

By maintaining stable surface contact, clean sanding conditions, and consistent pressure response, this type of disc aligns well with modern professional finishing requirements. For users focused on surface quality and repeatability, the flexible foam disc with multi holes provides a reliable solution for refined sanding processes.

www.goldenabrasives.com

China Golden Abrasives

Average Rating