Wheel Belt (Rotary Rings): Design, Function, and Applications in Modern Machinery

In modern industrial systems, reliable motion transmission components play a critical role in ensuring stable operation, efficiency, and long service life. Among these components, the wheel belt, also known as rotary rings, has become an essential element in many types of machinery. Its unique design and functional advantages make it especially valuable in complex industrial environments where continuous operation and precision are required.

Understanding the Design of Wheel Belts (Rotary Rings)

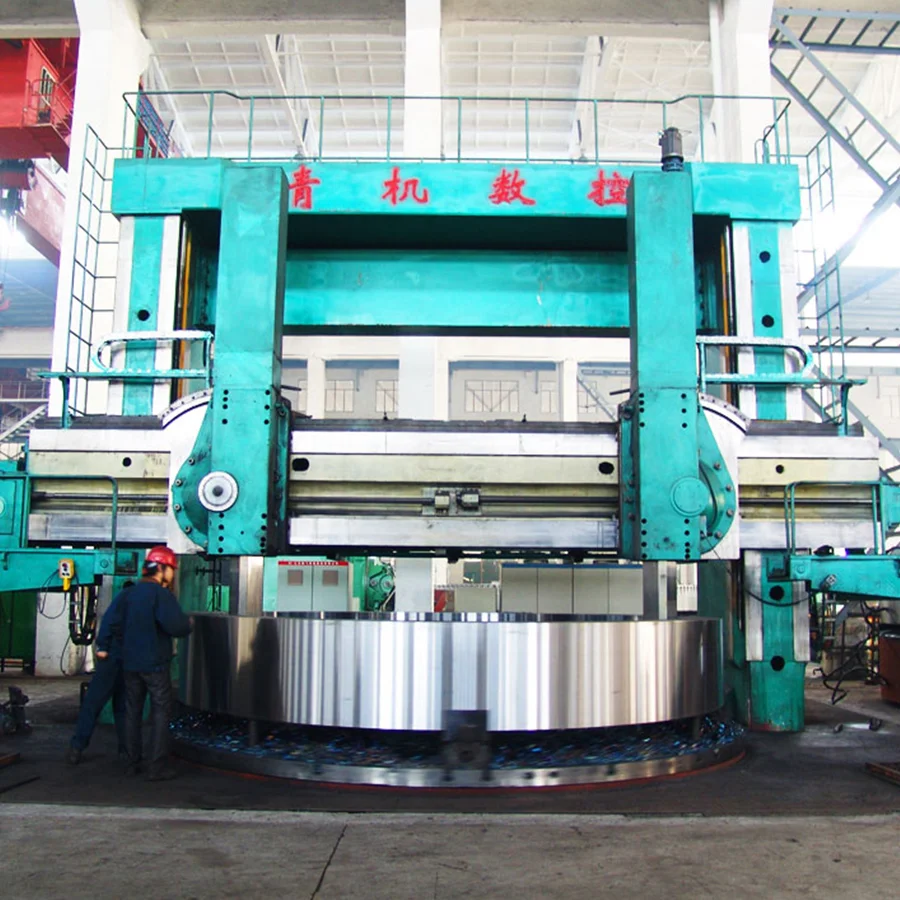

Wheel belts, or rotary rings, are circular transmission components designed to transfer motion and load between rotating parts. Unlike traditional linear belts or chains, rotary rings provide uniform contact and balanced force distribution around the circumference. This design helps reduce vibration, minimize localized stress, and improve overall system stability.

Modern wheel belts are typically manufactured from high-strength materials such as alloy steel, reinforced polymers, or composite materials. The choice of material depends on operating conditions, including temperature, chemical exposure, load intensity, and rotational speed. Precision machining and surface treatment further enhance wear resistance and dimensional accuracy, ensuring consistent performance in demanding industrial applications.

Core Functions in Industrial Equipment

The primary function of a wheel belt (rotary ring) is to transmit rotational motion smoothly and efficiently. By maintaining continuous engagement between moving components, rotary rings help synchronize mechanical processes and reduce energy loss. This is particularly important in systems that operate under heavy loads or require long-term, uninterrupted operation.

Additionally, wheel belts contribute to noise reduction and improved mechanical balance. Their circular structure supports even torque distribution, which lowers the risk of misalignment and mechanical fatigue. As a result, equipment equipped with rotary rings often experiences reduced maintenance requirements and longer service intervals.

Applications in Modern Machinery

Wheel belts (rotary rings) are widely used across multiple industries, including chemical processing, fertilizer production, and environmental protection systems. In large-scale industrial equipment, they are commonly applied in rotary reactors, dryers, mixers, and conveying systems where stable rotational movement is critical.

In the agricultural chemical sector, rotary rings play an important role in fertilizer production lines, supporting key processes such as granulation, drying, and cooling. Their ability to handle high loads and operate reliably in corrosive environments makes them well suited for applications involving phosphates, sulfur-based compounds, and compound fertilizers.

Supporting Complex Process Equipment at Sawei Equipment Technology

At Sawei Equipment Technology, the development of complete process equipment is at the core of its business. The company specializes in integrated equipment solutions for the agrochemical industry, including phosphate chemical processing, sulfur chemical systems, ammonium phosphate, and compound fertilizer projects. In these complex systems, wheel belts (rotary rings) are essential components that support the stable operation of large rotating machinery.

Sawei Equipment Technology also extends its expertise to the bio-fermentation industry, where industrial environmental protection and resource recovery systems are increasingly important. Applications such as carbon-containing waste gas treatment and waste oil recycling require robust and reliable mechanical components. Rotary rings used in these systems must withstand continuous operation and challenging environmental conditions, making design quality and material selection especially critical.

Advantages in Harsh Industrial Environments

One of the key advantages of wheel belts (rotary rings) is their adaptability to harsh operating environments. In chemical and fertilizer plants, equipment is often exposed to high temperatures, dust, moisture, and corrosive substances. Properly designed rotary rings provide excellent resistance to wear and corrosion, helping maintain stable performance even under extreme conditions.

This durability directly contributes to improved production efficiency and reduced downtime. By minimizing unexpected failures, wheel belts help operators maintain consistent output and control operating costs over the long term.

Future Trends and Industry Demand

As industrial equipment continues to evolve toward larger scale, higher efficiency, and greater automation, the demand for high-performance wheel belts (rotary rings) is expected to grow. Manufacturers and system integrators increasingly require customized rotary ring solutions tailored to specific process requirements.

With its strong focus on complete process equipment development and deep experience in agrochemical and bio-fermentation industries, Sawei Equipment Technology is well positioned to integrate advanced wheel belt solutions into future projects. By combining engineering expertise with reliable mechanical components, the company supports sustainable, efficient, and environmentally responsible industrial operations.

Conclusion

Wheel belts (rotary rings) are a vital component in modern machinery, offering stable motion transmission, durability, and efficiency across a wide range of industrial applications. From fertilizer production to environmental recovery systems, their role continues to expand as process equipment becomes more complex and demanding. Supported by experienced equipment developers such as Sawei Equipment Technology, rotary rings will remain a key element in the advancement of modern industrial machinery.

www.swasps.com

Jiangsu Sawei Equipment Technology Co., Ltd.

Average Rating