Why High Performance PLA Resin UBP-825 Is the Eco-Friendly Solution for 3D Printing and Extrusion Applications

The rapid growth of 3D printing and extrusion manufacturing has brought increasing demand for materials that combine high performance with environmental sustainability. Ubest’s UBP-825 PLA resin addresses both challenges by offering exceptional process stability, high-speed printing adaptability, and fully biodegradable properties suitable for extrusion and 3D printing applications.

1. High Cost Performance with Exceptional Printing Stability

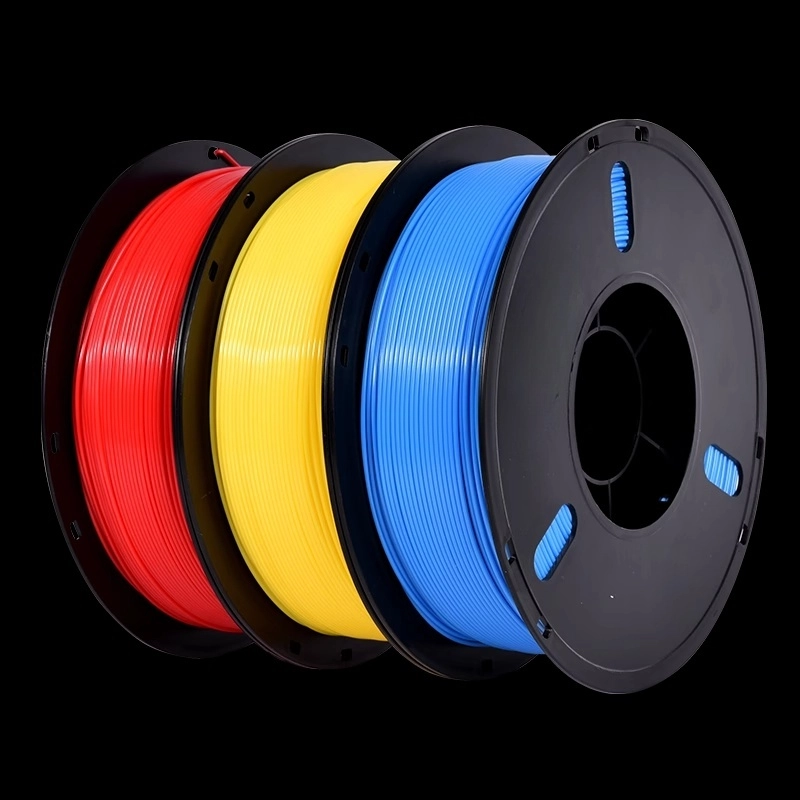

UBP-825 is engineered to provide a high cost-performance ratio, delivering superior results for industrial and commercial 3D printing without sacrificing quality. The resin maintains 100% neat wiring during extrusion, ensuring consistent layer deposition even at high speeds ranging from 30 mm/s up to 500 mm/s. This property is particularly crucial for high-speed extrusion 3D printing, where inconsistent filament flow can lead to defects and material waste.

The resin’s inherent toughness and semi-matte surface finish makes it suitable for both functional prototypes and end-use products, reducing the need for post-processing and enhancing overall production efficiency.

2. Eco-Friendly Biodegradable Composition

UBP-825 is derived from renewable plant starch resources, primarily corn, which is enzymatically converted to glucose and fermented to produce high-purity lactic acid. Polymerization then yields polylactic acid of controlled molecular weight. The fully biodegradable PLA resin can be completely decomposed by microorganisms in natural environments, eventually converting into carbon dioxide and water.

This “nature-to-nature” cycle positions UBP-825 as a zero-pollution material, meeting the growing demand for environmentally responsible 3D printing and extrusion solutions in industries seeking to reduce their carbon footprint.

3. Adaptability for High-Speed Extrusion and 3D Printing

High-speed extrusion often exposes limitations in standard PLA materials, such as warping, nozzle clogging, or inconsistent filament flow. UBP-825 is specifically designed to withstand extrusion rates up to 500 mm/s, providing smooth feeding and stable melt flow. Its thermal stability ensures consistent dimensional accuracy, while its moderate matte finish enhances print adhesion and reduces post-print finishing work.

This adaptability makes it ideal for industrial-scale additive manufacturing, including high-throughput prototyping, short-run production, and functional part fabrication.

4. Benefits Across Multiple Applications

UBP-825’s unique combination of performance and sustainability makes it versatile across various manufacturing applications:

-

3D Printing: Suitable for FDM/FFF machines, producing durable prototypes and functional parts with high dimensional precision.

-

Extrusion Products: Ideal for filament production, sheets, and profiles, maintaining consistent mechanical properties throughout processing.

-

Eco-Conscious Manufacturing: Aligns with green production initiatives in automotive, electronics, and consumer product industries.

By leveraging UBP-825, manufacturers can reduce material waste, enhance production efficiency, and meet environmental compliance standards simultaneously.

5. Operational Advantages for Manufacturers

UBP-825 PLA resin offers several operational benefits that make it a preferred choice for 3D printing and extrusion applications:

-

Consistent Feedability: Reduces downtime caused by filament jams or extrusion inconsistencies.

-

High Dimensional Accuracy: Ensures that printed parts maintain tight tolerances for functional applications.

-

Minimal Post-Processing: Semi-matte finish reduces the need for sanding or surface treatments, speeding up production cycles.

-

Thermal and Mechanical Stability: Maintains toughness under variable printing temperatures and speeds.

These advantages directly translate to higher throughput, lower operational costs, and enhanced overall productivity.

6. Industry Data Supporting PLA Adoption

Recent market studies indicate that PLA-based materials now account for more than 25% of global 3D printing filament consumption, with demand projected to grow by 15% annually. PLA’s biodegradability and lower environmental impact compared to ABS and other petrochemical-based resins are driving adoption in both consumer and industrial markets.

Ubest, with its annual production capacity of 100,000 tons, ensures reliable supply and consistent quality for global manufacturers, supporting expansion into markets such as Europe, Southeast Asia, India, and the United States.

FAQ

Q1: Can UBP-825 be used for high-speed 3D printing?

A1: Yes, it supports speeds from 30 mm/s to 500 mm/s without compromising filament stability or layer adhesion.

Q2: Is UBP-825 fully biodegradable?

A2: Yes, it decomposes naturally into carbon dioxide and water, achieving zero environmental pollution.

Q3: What industries benefit most from UBP-825?

A3: Automotive prototyping, electronics enclosures, consumer product manufacturing, and extrusion applications all benefit from its performance and sustainability.

Q4: How does UBP-825 reduce post-processing work?

A4: Its semi-matte surface and uniform extrusion reduce the need for sanding, finishing, or rework.

Q5: Is supply reliable for large-scale production?

A5: With an annual production capacity of 100,000 tons, Ubest guarantees stable supply for industrial-scale operations worldwide.

By integrating UBP-825 high-performance PLA resin into 3D printing and extrusion workflows, manufacturers can achieve eco-friendly production, reduce material waste, and maintain high output quality. Ubest’s commitment to innovation, sustainability, and supply reliability ensures that UBP-825 meets the needs of modern, environmentally conscious manufacturers across global markets.

www.wxubest.com

Wuxi Ubest New Material Technology Co., Ltd.

Average Rating