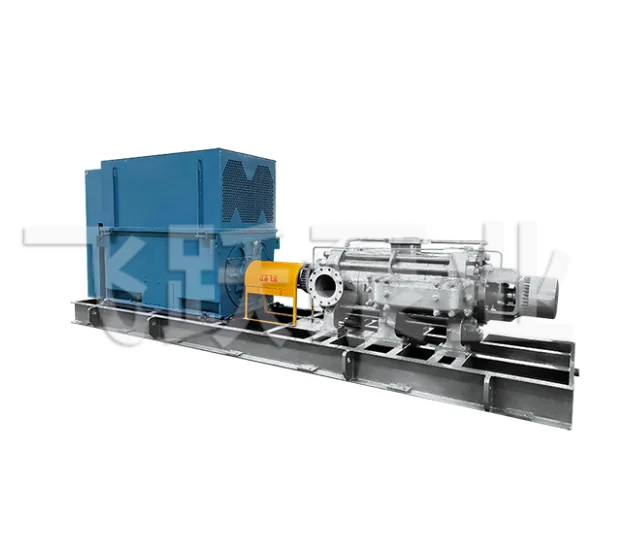

Wear-Resistant Multistage Centrifugal Pump for Fluid Handling

A wear-resistant multistage centrifugal pump plays a pivotal role in many industries by efficiently transporting high-pressure fluids while ensuring durability and reliability under demanding conditions. This type of pump is specially designed to handle abrasive media, such as slurries, mud, or water containing sand and gravel, making it essential for industries like mining, construction, and wastewater treatment. In this blog post, Feiyue, as high quality multistage centrifugal pump manufacturing factory, will share the benefits of wear resistant multistage pump for fluid handling.

What is Wear-Resistant Multistage Centrifugal Pump?

A wear-resistant multistage centrifugal pump is a type of pump that consists of multiple impellers and guide vanes arranged in stages. As fluid flows through each stage, its pressure is progressively increased, resulting in high-lift delivery. The defining characteristic of this pump is its ability to resist wear caused by solid particles and abrasive media. Through careful material selection, surface treatment, and structural design, these pumps can withstand harsh conditions and operate reliably over extended periods.

Key Components and Working Principles

The key components of a wear-resistant multistage centrifugal pump include:

-

Impellers: The rotating blades that transfer energy to the fluid.

-

Guide Vanes: Fixed blades that help direct the flow of fluid and maintain optimal flow conditions.

-

Pump Shaft: A component that transmits the mechanical energy to the impellers.

-

Casing: The outer structure that houses the pump components and directs fluid flow.

The working principle of a centrifugal pump is based on converting mechanical energy from the motor into kinetic energy of the fluid, which then flows through the pump and exits at high pressure. In a multistage pump, the fluid passes through several impellers arranged in series. Each stage increases the pressure of the fluid, allowing the pump to handle higher lift requirements.

Advantages of Wear-Resistant Materials in Pump Design

The wear resistance of a centrifugal pump is crucial for ensuring longevity and reliability, especially when handling abrasive or solid-laden fluids. To achieve wear resistance, manufacturers utilize advanced materials and surface treatments:

-

Special Alloy Materials: Wear-resistant alloys, such as stainless steel or high-chromium iron, are used to create impellers and other critical components that can withstand erosion from solid particles.

-

Surface Coatings: Hard coatings or ceramic liners are often applied to components that experience high wear, adding an extra layer of protection against abrasive forces.

-

Structural Design: Pumps are designed with reinforced components and advanced sealing techniques to minimize wear and maintain consistent performance under high-stress conditions.

These innovations enable wear-resistant multistage centrifugal pumps to deliver superior performance in harsh environments, such as mining, dredging, and slurry transport applications.

Applications of Wear-Resistant Multistage Centrifugal Pumps

Wear-resistant multistage centrifugal pumps are used in a wide range of applications that involve handling abrasive and solid-laden fluids. Some of the most common industries and applications include:

1. Mining and Mineral Processing

In the mining industry, centrifugal pumps are used to transport slurry and other abrasive fluids that contain minerals, sand, and gravel. Wear-resistant pumps are essential for this application, as they can handle the rough nature of these media without suffering from excessive wear. Whether transporting slurry in processing plants or handling tailings, these pumps provide the necessary durability and efficiency for mining operations.

2. Water and Wastewater Treatment

In wastewater treatment facilities, centrifugal pumps are used to move wastewater and sludge that may contain suspended solids, grit, and other abrasive materials. Wear-resistant pumps are essential for handling these media over extended periods, ensuring the facility operates smoothly without frequent downtime due to pump failure.

3. Agriculture and Irrigation

For large-scale irrigation systems, wear-resistant multistage centrifugal pumps are used to move water over long distances. These pumps often need to handle water with varying levels of debris, such as soil or organic matter. Wear-resistant pumps ensure that the system continues to function without the need for constant maintenance.

4. Construction and Dredging

In construction and dredging operations, pumps are often required to transport water mixed with sand, mud, or other heavy materials. These environments are highly abrasive, making wear-resistant centrifugal pumps a perfect solution for ensuring long-term operation without performance degradation.

Why Choose Wear-Resistant Multistage Centrifugal Pumps?

Investing in wear-resistant multistage centrifugal pumps offers numerous advantages for industries dealing with abrasive fluids. Some of the key benefits include:

1. Extended Service Life

Due to their specialized materials and design, wear-resistant pumps can operate for much longer periods than conventional pumps. This reduces the need for frequent maintenance and part replacements, ultimately lowering operational costs.

2. High Efficiency

Multistage centrifugal pumps are highly efficient in transferring fluids at high pressures. Their ability to handle large volumes of abrasive media without compromising performance ensures that they deliver optimal results for fluid handling applications.

3. Reliable Operation Under Harsh Conditions

Wear-resistant pumps are specifically engineered to perform reliably in tough environments, including those with high wear conditions. Whether you're dealing with slurry, sand, or other abrasive substances, these pumps can handle the load while maintaining stable performance.

4. Reduced Downtime

Because of their ability to resist wear and tear, these pumps experience less frequent breakdowns compared to traditional pumps. This leads to increased uptime, ensuring that operations run smoothly without interruptions.

Maintenance Tips for Wear-Resistant Multistage Centrifugal Pumps

While wear-resistant multistage centrifugal pumps are designed to handle tough conditions, regular maintenance is still essential for optimal performance. Here are some maintenance tips to ensure longevity and efficiency:

-

Regular Inspection: Check for signs of wear, especially on the impellers and seals. Replace any worn components before they cause further damage.

-

Proper Lubrication: Ensure that the pump's bearings and shafts are properly lubricated to prevent friction-related wear.

-

Cleaning: Periodically clean the pump to remove any buildup of abrasive materials that could affect performance.

-

Monitoring Performance: Keep track of key performance indicators, such as flow rate and pressure, to identify any potential issues early on.

Conclusion

A wear-resistant multistage centrifugal pump is an indispensable tool for industries requiring high-lift fluid handling, particularly when dealing with abrasive materials. Through advanced material selection, innovative design, and robust surface treatments, these pumps deliver outstanding performance and durability. By choosing the right pump and maintaining it properly, businesses can ensure continuous, efficient operation in even the harshest conditions, resulting in long-term savings and productivity gains.

www.jsfeiyuepump.com

Feiyue

Average Rating